Shop profile: The art of parts

Shop profile: The art of parts

A prototyping shop relies on CAD/CAM software and advanced cutting tools to combine innovation and art.

By CNC Software Inc.

One of the laments of machinists is that part designers don't always consider whether their creations actually can be made. Brian Ross, founder of Form Factory Inc. in Portland, Oregon, embraced that thought and turned it on its head. He created his company to cater to clients in a variety of industries that all need one thing: high-precision prototypes.

"People who are developing new products come to us, and we help them prototype and invent their ideas," he said. "Largely, we're just working as a piece of the puzzle to help get a product out into the real world — out of somebody's brain."

To achieve this, Ross tries to channel the thinking process of a part designer and then marry it to the thinking process of a machinist. In doing so, he has carved a unique niche for his company.

Becoming a fixture in the prototyping market wasn't originally part of his plan. When he accepted a position at a job shop before his junior year of college, he thought that it would be only a summer job that he easily could forget about come fall. Four years later, he was still at the same shop and had worked his way up to running its first CNC machine.

Brian Ross founded Form Factory in 2004. Image courtesy of CNC Software

"After about four years, I started realizing there's more than just cutting pockets and holes out of a sheet," Ross said. "At that time, I had never flipped a piece of stock over and machined the other side or done multiple operations or setups from different orientations. I wanted to know more, so I put myself through night school for the Mastercam certification courses."

Mastercam certification helped him land jobs at multiple prototyping companies.

"I worked at four different really strong prototyping firms very similar to Form Factory," Ross said, "and I think I got enough from each of them to put together my own place after about 10 years."

The decade he had spent learning terminology, processes, marketing and funding made his transition to business owner that much easier. When he founded his company in 2004, he bought a new, built-to-order Haas machine tool and a seat of Mastercam, and he's been growing his business ever since.

"We pride ourselves on always being on time and always having happy customers," Ross said, "but sometimes that comes at the cost of making a part for the third time or working excessive overtime or even pulling an occasional all-nighter."

A Creative Approach

Seventeen years later, he has built a respectable reputation for Form Factory and expanded his team to include a model-maker, a maintenance helper, a bookkeeper and three CNC machines. His approach to serving customers focuses on quality and ingenuity, not necessarily speed.

"A lot of shops really are geared toward pallet changers and automation and ripping through material as fast as possible," Ross said. "We really specialize in low volume and creativity."

Brian Ross holding one of his creations. Image courtesy of CNC Software

From 80% to 95% of Form Factory's jobs involve machining one to five copies of a prototype. Attention to detail is vital in these situations; tolerances are often within 0.0254 mm (0.001").

"Some projects, we're doing iteration after iteration trying to get a product to market," Ross said. "Sometimes we're only doing one little mechanical detail, but we'll do it again and again to get some functionality to work just right. Then that's incorporated into the design, and ultimately we can make a hard model that looks just like the real thing."

Early in design exploration, a basic form factor model frequently is machined out of high-density urethane foam or tooling board, which can be fragile and difficult to work with. Every aspect of prototyping calls for great accuracy, so he has organized his own collection of resources to enable this. For example, Rowley, Massachusetts-based Harvey Performance Co. LLC's Harvey Tool and Helical Solutions brands provide carbide endmills and other cutting tools that allow him to turn his products into art.

"To me, machining is sculpture," Ross said. "I've always tried to make parts that look like they grew that way. I've learned to use Harvey's special little cutters to deburr what you can on the machine instead of doing that by hand so that it comes off completely finished."

He also prefers tapered endmills and long-reach tools that help him rough what he calls "impossible reaches" — tight pockets that are extremely difficult to access with typical tool lengths. He prefers tools designed specifically for aluminum applications.

Seats at the Table

Ross has worked with his Mastercam reseller, MCAM Northwest Inc. in Oregon City, Oregon, since day one. Tim Rowley, founder of MCAM Northwest, and his team provide technical support for Form Factory's two seats of Mastercam Mill 3D, one seat of Mastercam Multiaxis and one seat of Mastercam Design. Rowley updates the software and offers extra support for rollouts to help ensure high-precision prototyping as well.

The vast majority of Form Factory's jobs involve machining one to five copies of a prototype, such as this one for a notebook computer. Image courtesy of CNC Software

"He's looking for surface finishes that are way beyond what most shops that do prototyping are," Rowley said. "He's always pushing the boundaries."

The CAD/CAM software has features that simulate the machining process, highlighting any potential collisions and checking the quality of toolpath motion. In addition, a function in the software's simulation tool uses an intuitive, color-coded interface to allow users to easily compare verification results with the model.

"The minute I try to make a setup part or a practice run, I've already taken all of the profit out of a job," Ross said. "I have to succeed on my first go."

To take full advantage of Harvey's specialty cutting tools, he uses the software's Dynamic Motion technology, or Dynamic Milling. Dynamic toolpaths follow a proprietary algorithm that constantly monitors material as it is cut. As the machine works, Dynamic toolpaths detect any changes in material and calculate necessary adjustments to feeds, speeds, step-overs or cutting motions to keep machining safely. He said the results are a 90% reduction in roughing times, fewer air cuts and tripled tool life.

"Some of the software's high-efficiency machining allows you to use the entire flute of that cutter rather than dulling the very tip of the cutter," Ross said. "In the old days, you'd have 90% of the cutting flute sharp as day, but you'd have to throw that tool out and start again. Now, you can get way better tool life and prep things much faster, and you still have reasonably sized chips."

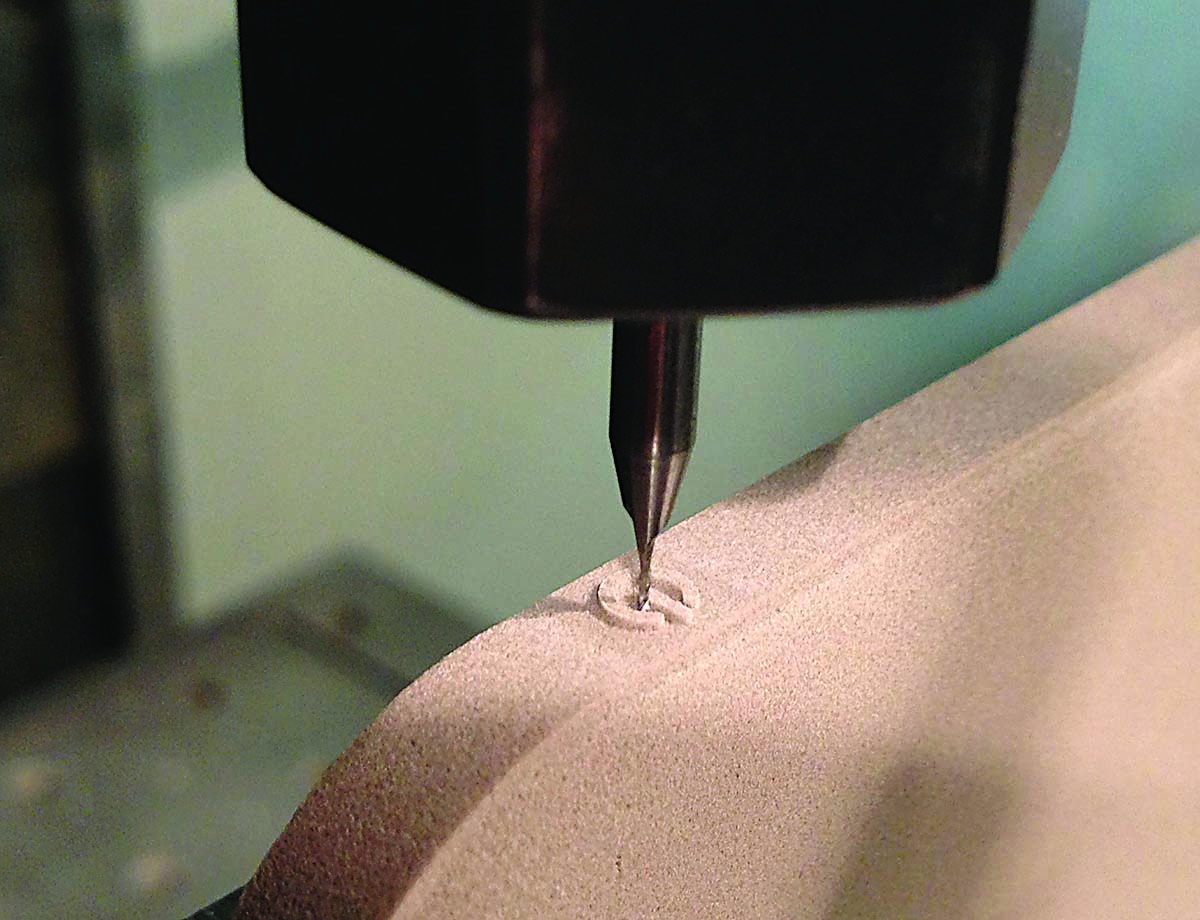

A microendmill is applied at Form Factory to create a Thanksgiving plaque. Image courtesy of CNC Software

Dynamic toolpaths also include a rest milling option, which removes material left by previous operations. For example, if a scallop is left in a corner by a cutting tool with a diameter too large to remove it, the software automatically will plan to remove the scallop with a smaller-diameter tool.

"You could spend days and days trying to figure out where you need to cut this leftover material," Ross said, "so being able to use the rest milling feature and just cut specifically where you need to is really helpful."

Sometimes issues arise but not because of machining error.

"Some of our successes that we have here at Form Factory from a design standpoint are the failures," Ross said. "When somebody's idea fails, at least we answered that question early on and save our customers future headaches and costs further down the road. You prototype to figure out what works and what doesn't."

He works on prototypes with customers for as long as it takes to find effective solutions.

Considering he often has to turn away work, Ross said he could expand the company. However, he prefers to operate Form Factory at the local level. The rapport he has built with clients and his company's ability to customize every part are too valuable to compromise. He soon may bring on another employee or two, but Form Factory is focused on maintaining its standards of quality, creativity and precision.