Swiss-style CNC lathes gaining popularity

Swiss-style CNC lathes gaining popularity

Machine shops enjoy additional opportunities with sliding headstock lathes.

From turret lathes and machining centers to cylindrical grinders and EDMs—all machine tools present unique demands. Swiss-style turning centers, however, are in many ways more difficult to program and operate than any of the machinery just listed but offer greater opportunities for improvement. These include higher-quality parts, increased throughput and—for shops that don't yet have a Swiss-style lathe—possibilities for new business and for higher profitability on existing work.

Let Me Count the Ways

Just as it might be challenging to maneuver a Formula One circuit with a school bus, turning parts less than 1" in diameter is not optimal on a turret lathe:

- At 6,000 rpm or less, spindle speeds are often woefully inadequate on an 8" or 6" chuck CNC lathe.

- It can be difficult to achieve the perfect centerline needed for turning small parts with turret-mounted tools.

- Smaller parts frequently are turned using dead-sharp inserts with small nose radii, which may be tough to find for the 1" shank and larger stick tools typically found on most turret lathes.

- Because small parts require less horsepower to machine, using a large lathe to produce them is about as wasteful as towing a bicycle with a pickup truck.

Turret lathes are also slower.

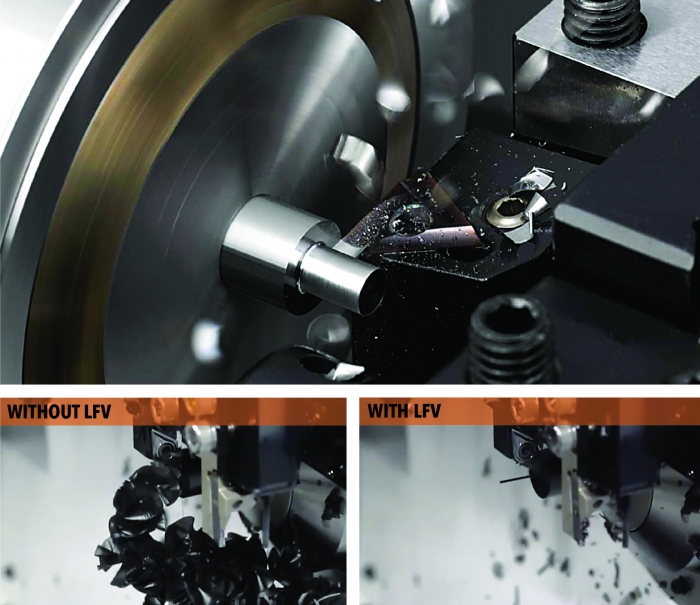

LFV assures that what otherwise would have been a monstrous stringer is broken into manageable chips. Image courtesy of Marubeni Citizen-Cincom

"Swiss-style lathes generally have a very small work zone, much smaller than the typical CNC lathe, and use gang tooling rather than a turret," said Derek Briggs, Swiss product manager at Tsugami/Rem Sales LLC, Windsor, Connecticut. "Because you're only moving a very short distance to change tools rather than going all the way home, indexing the turret and coming back, chip-to-chip time is very fast. That's where a Swiss machine can really beat out a conventional lathe."

Avoiding the Wad

Shorter cycle times notwithstanding, small work zones are a double-edged sword. The wad of chips that falls to the chip tray on a turret lathe can quickly become pinched between the workpiece and tool on a crowded Swiss-style machine. Aside from the annoyance and lost revenue associated with stopping production at regular intervals to pull bird nests from the machine interior, poor chip control may mar part surfaces, break cutting tools and damage machine tools. Long, stringy chips can be especially problematic when turning stainless steel, platinum and cobalt-chrome alloys, materials commonly used for the tiny screws and other medical components frequently turned on Swiss-style machines.

Some Swiss-style machine tool builders have addressed this particular problem with a control feature that Briggs calls oscillation cutting. By oscillating the axis back and forth in conjunction with spindle rotation as the tool feeds into the workpiece, the chip breaks into manageable pieces.

"We cut some parts at a customer's facility recently with and without oscillation cutting," he said. "With it turned off, we had to stop the machine after 10 parts to clear the chips. With it turned on, the chips broke into little sixes and nines, which is exactly what you want. It's fantastic."

These Ti-Loc extensions make it easier to reach a part in tight clearance situations. Image courtesy of Genevieve Swiss Industries

Marubeni Citizen-Cincom Inc., Allendale, New Jersey, similarly has developed LFV, short for low-frequency vibration. LFV uses "perfect phasing" like that found on a C-axis to create what is essentially a serration in the material, breaking the chips on even very stringy Teflon or MP35N nickel-cobalt alloy, said Executive Vice President Brian Such.

"Since we can adjust the number of serrations per spindle rotation," he said, "there's really nothing that we can't break, even when the tool is moving in multiple axes simultaneously, as when interpolating an angle or cutting a radius."

Another production element that many Swiss shops struggle with is long setup times. This is why Tsugami/Rem Sales has partnered with quick-change tooling manufacturer Göltenbodt Technology GmbH, Leonberg, Germany, and Marubeni Citizen-Cincom recommends the QS holding system from Sandvik Coromant Co., Fair Lawn, New Jersey. Both systems can simplify and speed up the tool-changing and setup processes.

These systems help in other ways as well. Because they contain internal coolant channels and precision ports, they increase cutting fluid efficiency and eliminate the copper or plastic lines that tend to catch stringy chips.

"Instead of installing lines at each tool position and having to adjust them every time you set up a job, you can run high-pressure coolant right through the baseplate to the tip of the tool," Briggs said. "It solves a lot of problems."

Too Much Going On

It's hard for humans to watch more than one thing at a time. Considering that Swiss-style lathes not only move quickly but often boast a subspindle, dozens of tools and the ability to simultaneously perform multiple turning and milling operations, this makes the possibility of a crash quite real. Such has a solution.

Although the company's name has changed from Heimatec Inc. to Platinum Tooling Technologies, it remains the exclusive importer of Heimatec GmbH tooling in North America. Image courtesy of Platinum Tooling Technologies

"Practically all other CNCs have a rapid override," he said. "Citizen machines don't. Instead, there's a process override, which lets the operator slow the rapids, the feed rates and even the M codes, all with the same knob and all at once. Timing is everything on a Swiss. Our solution eliminates the situation where a tool that cleared the workpiece or subspindle with the rapid override set to 25% will hit when you turn it to 100%. Nothing is ever out of sync."

Swiss-style machine tool builders also offer features such as pneumatic, self-adjusting guide bushings, reducing the need for ground bar stock. "Chucker convertible" options allow the sliding headstock to move in the forward position, eliminating the guide bushing. Convertibles also reduce the length of bar remnants—a big concern with expensive, medical-grade materials—and enable the machine to be operated as a chucker, further expanding its capabilities.

With Swiss-style CNC lathes becoming more popular, Scott Laprade, applications and technical sales representative at Genevieve Swiss Industries Inc., Westfield, Massachusetts, pointed out that the number of tooling choices available to lathe owners is on the rise.

"For example, we've recently expanded our live tool offering with compact, planetary-geared drilling and milling attachments that offer much higher spindle speeds and consume less space in the machine's working area," he said. "With that, we offer a range of quick-change, ER-style Ti-Loc extensions that make it easier to reach the workpiece in tight clearance situations."

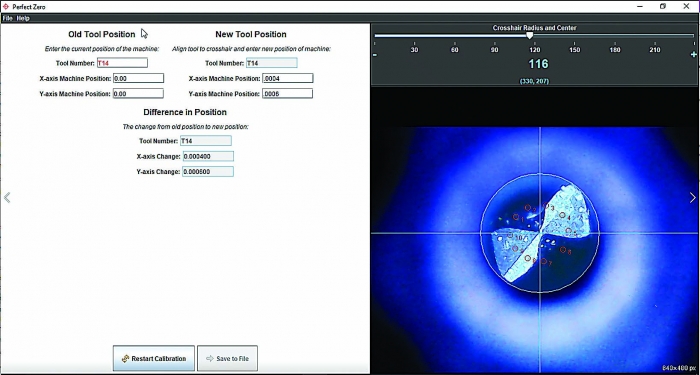

GenSwiss' Perfect Zero system helps machine operators correct tool alignment problems. Image courtesy of Genevieve Swiss Industries

Getting tools exactly on center normally could be a challenge for Swiss machines, especially with tiny boring bars and drills, where even the slightest deviation from centerline can mean a broken tool. But Laprade said GenSwiss' Perfect Zero alignment system solves this problem.

"The kit contains a laptop with pre-loaded software and a camera that goes in the guide bushing," he said. "You call up a tool, align it with the camera's crosshairs and instantly know how much misalignment is present. You can then make an offset to correct it or a mechanical adjustment if necessary. And for rotating tools, there's a calibration process you can use to minimize runout or eccentricity."

A Platinum Hit

Platinum Tooling Technologies Inc., Prospect Heights, Illinois, is another Swiss-oriented tooling distributor. President Preben Hansen explained that he recently rebranded his company, Heimatec Inc., to expand his nearly decadelong exclusive relationship with Heimatec GmbH, Renchen, Germany. Heimatec GmbH's live tooling line now includes live and static tools for Marubeni Citizen-Cincom machines, and Platinum Tooling Technologies also offers Swiss collets and guide bushings from Tecnicrafts Industries and IB spindle speeders from Suzuki Precion Co. Ltd.

Speeder heads like the one shown provide the high rpm needed for small cutting tools. Image courtesy of Platinum Tooling Technologies

"Swiss shops use a lot of very small drills and endmills," he said, "and the available driven tool speeds don't always provide the rpm needed for tiny cutting tools."

He suggests that shops keep a close eye on the cutting tool and whatever it machines, no matter whose logo sits on the live toolholder. Once surface finish begins to diminish or runout moves beyond a couple of tenths, he said, that's a good indication it's time to send out the live tool for a rebuild. If a shop waits too long, bearings could seize, possibly destroying an expensive piece of tooling.

He further recommends ultraprecision collets and guide bushings, which can make the difference when a finish cut is wanted on the bar's exterior, thus saving precious seconds of cycle time.

"Most customers go for the ultraprecision, knowing that it provides 5μm maximum runout for a fairly small cost delta," he said.

Considering the broad array of tooling options, faster setups and machines that are easier to operate than before, he said use of Swiss-style CNC lathes is becoming more widespread. Still, not everyone has seen the light.

"Traditional turning shops should avoid pigeonholing themselves with fixed-headstock, turret-only machines," he said. "They need to broaden their customer base, and Swiss-style lathes are a great way to do that. And if they're already producing smaller parts, the chances are excellent that a modern Swiss machine will make them faster and more accurately."