Vibratory finishing’s mass appeal

Vibratory finishing’s mass appeal

Deburring parts with vibratory finishing equipment is a cost-saving and more consistent alternative to manual deburring.n

Vibratory, or mass, finishing is frequently viewed as the "bastard" secondary operation, said Ken Raby, vice president and general manager of Walther Trowal LLC in Byron Center, Michigan.

"That's what we are," he said. "We are in the booths in the back, in the corner, in the dark where parts go to get deburred, but nobody wants to go back and work there."

Raby said a lot of manufacturers of machined parts outsource mass finishing — not just for deburring but for surface finishing and polishing, cleaning, edge radiusing, descaling and pickling — because companies don't want to deal with the wastewater that the process generates or the labor requirements. Nonetheless, when the applications are appropriate for deburring machined parts in a vibratory tub or bowl and the finishing equipment and consumables are well suited for the types of parts and volumes produced, mass finishing adds significant value.

"If (shops) are looking at a more consistent process and bringing value to the finishing operation, those are the right (shops) to invest in a finishing operation," said Bernie Kerschbaum, CEO of Battle Creek, Michigan-based Rosler Metal Finishing USA LLC. "If they see mass finishing as a necessary evil because somebody put it in a print, then they might let a job shop handle it."

Saving Labor

Even with a record number of people becoming unemployed because of the pandemic, manufacturers continue to struggle to attract workers.

"We are constantly trying to find ways to increase automation," said Sales and Marketing Manager Cole Mathisen at Mass Finishing Inc. in Howard Lake, Minnesota. "That's a big thing."

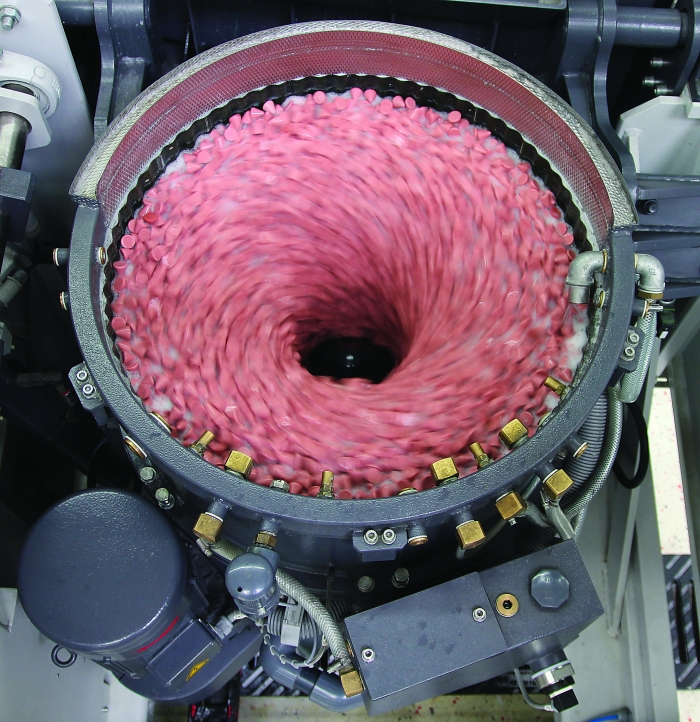

Parts are deburred in a vibratory finishing machine. Image courtesy of Walther Trowal

Part manufacturers also are seeking to retain the workforce already in place by improving working conditions through stress reduction.

"The main focus for a lot of companies is ergonomics," Mathisen said, "making sure workers are not having to do a lot of lifting and bending."

Kerschbaum concurred that Rosler Metal Finishing USA is seeing robust demand for automation equipment for finishing operations. Automation is suitable for vibratory bowls and tubs, he noted, but it is more challenging than automating drag finishing equipment in which parts are fixtured.

He said another type of finishing equipment that's relatively easy to automate is high-energy disc machines. When they are automated, an operator simply brings a bin of unfinished parts to a loading station and removes a full bin of finished, dried parts from the machine.

Even without automation, vibratory finishing machines reduce the amount of labor needed to deburr and otherwise finish parts by hand. Raby said Walther Trowal has a customer in Mexico that employed 90 workers to manually finish plastic parts before purchasing several pieces of mass finishing equipment.

"There the payback was huge," he said. "All of our machines are more or less sold on a payback."

Raby said return on investment for finishing machines is typically less than a year.

In addition to reducing the number of workers needed to deburr parts, mass finishing significantly reduces the scrap rate.

"It's hard to find the lunch pail guys, so to speak, who are willing to clock in at 8 and work until 5 and make every part from part one to part 500 look identical," Mathisen said. "It's appealing to have some sort of hands-free process where those pieces are taken care of by equipment."

He said a high-energy centrifugal barrel finisher is one equipment option that offers benefits, such as quiet operation.

"There's no vibration," Mathisen said about high-energy equipment. "It's all centrifugal force, almost like a Ferris wheel."

He said nonvibratory equipment is effective for deburring hardened material, sometimes removing burrs in an hour that a vibratory tub was unable to remove.

"It's extremely high energy," Mathisen said, "and the G-forces involved are upward of 12 G compared with 1.5 G you see in the vibratory equipment."

He said centrifugal tumblers also are able to impart a finer surface finish than vibratory tumblers.

Media Choices

When deburring and otherwise finishing parts in a vibratory machine, end users have two basic media materials to choose from: ceramic and plastic. Kerschbaum said ceramic is more economical per running hour and available in a wider range of shapes and sizes, as well as suitable for finishing relatively hard metals, such as carbon steel and stainless steel.

On the other hand, plastic media, which is molded to a specific size and shape, has a lower density than ceramic media and generally is used for finishing aluminum and other nonferrous parts. But Raby said parts made of a sintered ferrous metal can be somewhat delicate and should be treated like nonferrous parts.

A disc machine is displayed operating with plastic media. Image courtesy of Rosler Metal Finishing USA

According to Walther Trowal, pressure deburring, or ball burnishing, also can be performed in small trough vibrators with steel media.

Kerschbaum said chipping is a concern with ceramic media, so it is more prone to cause impingement, especially in part features like blind holes.

"It's not a problem for 95% of parts," he said. "For those parts where there is a concern, a plastic media would be the alternative."

Mathisen said ceramic and plastic media have abrasive material that is baked, or mixed, into a piece.

"The plastic gives a little better surface finish on nonferrous parts," he said.

In addition to deburring with a low-density media, delicate parts require a higher media-to-part ratio than robust workpieces. Kerschbaum explained that a 3-1 ratio of media to parts is a good starting point for delicate parts while a 1-1 ratio is appropriate for raw forgings and other parts that are not so delicate. For highly delicate parts, such as brass ones with seating surfaces, the ratio might need to be increased to 10-1.

Mathisen said when seeking to entirely eliminate part-on-part damage, chambers on high-energy centrifugal barrel tumblers, for example, can be created for individual parts.

"They have their own little section and are not damaging other parts," he said. "You can divide tubs but not to the extent or ease you can with our barrel tumblers."

On the flip side, Mathisen said some low-value parts, such as fasteners and pins, basically are run part on part.

"The equipment is just kind of vibrating the parts against each other," he said, "and they deburr themselves."

Clean Machine

A compound, or soap, also is needed when mass finishing parts. Regulations vary based on where a facility is located, but effluent typically can't be dumped down a drain or deposited in a septic field.

"Wastewater disposal is something that I always bring up because I don't want to be involved in a lawsuit if a customer isn't taking care of it correctly," Raby said. "I've gotten my butt in trouble trying to recirculate wastewater from a mass finishing application in the past before joining Walther Trowal, and they didn't work."

His company offers a wastewater recirculation system for vibratory finishing applications that recirculates water for about four months before it needs to be disposed properly. The system can be installed on new equipment or retrofitted to existing finishers from Walther Trowal or other manufacturers.

"One customer was going through 330 gallons (1,249 L) of soap a month," Raby said. "We put a wastewater centrifuge in, and they started going through 30 gallons (114 L) of soap per month because they were able to recapture and reuse it."

Accelerated chemistry, which is essentially a type of acid, is available to increase finishing speed. Mathisen said accelerated chemistry softens part surfaces while the media rubs against them. He noted that Mass Finishing doesn't recommend the chemistry for barrel tumblers because the process can be so aggressive that processing speed isn't an issue and it's dangerous to have the chemistry inside a closed chamber.

Tommy Mathisen, co-founder and director of technology at Mass Finishing, operates a custom 600-L (159-gal.) centrifugal barrel tumbling machine, which features four barrels with chambers measuring 1,575 mm long × 305 mm wide (62"×12"). Image courtesy of Mass Finishing

"It's a process that you have to dial in, and it takes a lot of testing," he said. "If you have high-volume, lower-value parts that you're just trying to do quickly, it can be appealing."

Kerschbaum agreed that there is justification for accelerated chemistry, such as when a high level of polish is specified or when finishing hard-to-access gear teeth, but those applications are the exception rather than the rule.

"When you have accelerated chemistry," he said, "you have a lot more concerns about waste disposal than with what we call a neutral mass finishing process, especially if you can run that in a recycling system. If we can do a neutral process, we will."

When fine-tuning a mass finishing process, Kerschbaum said up to 15 different parameters exist. He recommends reaching out to finishing experts to gather additional insight for developing the most efficient, cost-effective process.

One possible way to reduce costs is to shift work from a high-value CNC machining operation to a lower-cost mass finishing operation.

"Can they run a faster feed on their CNC machine because the burr still comes off in a half-hour in the mass finishing equipment?" Kerschbaum said.

The cost of a decent CNC machine might start at $200,000 with no limit in sight.

"Mass finishing, unless you go all-out with automation, you're talking prices from $20,000 to $200,000," Kerschbaum said. "If you design that well, you will have an extremely value-added process that helps you make money."

Although the return on investment for a mass finishing machine can be fairly quick, mass finishing is a long-term investment. With a few simple modifications, such as changing the media and compound, he said an end user can continue to use the equipment when parts change.

In addition, regular maintenance, such as replacing bearings, shafts and motors, can keep equipment up and running for a long time. Besides selling machines and consumables, Rosler Metal Finishing USA relines and rebuilds equipment.

"We recently did a machine that was about 50 years old," Kerschbaum said. "The machines last."

For more information about vibratory mass finishing, view a video presentation by Walther Trowal at www.ctemag.com by scanning the QR code with your smartphone or entering this URL on your web browser:

cteplus.delivr.com/2wt6z

Circular Vibrators Handle Radiusing of Carbide Inserts

Similar to other part manufacturers, producers of cutting tools seek to boost productivity while enhancing part quality. Sometimes, however, this existential principle of profitability is blocked by technology process restraints.

A European toolmaker needed to overcome these limits when manufacturing carbide inserts. Toolmakers typically reject about 20% to 30% of each batch of inserts because of chipping when edge radiusing them using vibratory mass finishing — an economically unacceptable situation.

Traditionally, two different vibratory mass finishing machines are used: one that runs at a lower amplitude and higher rpm and one that runs at a higher amplitude and lower rpm, said Ken Raby, vice president and general manager of Walther Trowal LLC. An alternative is to use only one machine and change the weights and settings to alter the amplitude and rpm, but it's a time-consuming, challenging process.

"Just by transferring them from one bowl to another," he said, "you could potentially damage the carbide inserts."

The insert manufacturer worked with Haan, Germany-headquartered Walther Trowal GmbH & Co. KG to develop a solution. Walther Trowal reported that the process it developed is based on reversing the machine rotation in conjunction with a frequency converter, a miniature programmable logic controller and an adjustable imbalance generator.

Initially, Walther Trowal changed the rpm with the frequency converter and PLC but manually adjusted the weights to ensure that the process functioned effectively, Raby said. Once the process was proven, an adjustable imbalance generator was added to automatically change the amplitude, enabling one machine to produce two defined amplitudes from 1 to 10 mm (0.039" to 0.394"). The rpm ranges from 950 to 3,600, but running at the highest speed would damage or destroy the machine even when the amplitude is 1 mm.

He said the toolmaker originally purchased one CM 305-S modular circular vibratory finishing machine and quickly added more machines after reducing costs through process optimization and minimization of nonproductive times. Walther Trowal offers six CM models. In addition, the company increased the volume of inserts that could be processed at one time because each new machine has a total working capacity of 0.19 cu. m (6.7 cu. ft.) compared with the previous vibratory tub's capacity of 0.014 cu. m (0.5 cu. ft.).

— Alan Richter