6-D Laser officially launches in 2020

6-D Laser officially launches in 2020

6-D Laser LLC was formed in 2018 as an affiliate of leading nanometer-level motion control specialist ALIO Industries, with the mission of integrating ultrafast laser processing with precision multiple-axis motion systems. 6-D Laser offers Hybrid Hexapod-based laser micromachining systems for wide-range taper angle control, 5-axis laser Gimbal-based systems for laser processing 3D substrates, and unlimited field of view scanning solutions for laser processing large-format substrates.

6-D Laser LLC was formed in 2018 as an affiliate of leading nanometer-level motion control specialist ALIO Industries, with the mission of integrating ultrafast laser processing with precision multiple-axis motion systems. 6-D Laser offers Hybrid Hexapod-based laser micromachining systems for wide-range taper angle control, 5-axis laser Gimbal-based systems for laser processing 3D substrates, and unlimited field of view scanning solutions for laser processing large-format substrates.

Coming out of stealth mode and coinciding with its official launch in 2020, 6-D Laser has launched its website (www.6dlaser.com).

6D Laser's central mission addresses limitations of existing laser processing systems, which are largely due to suboptimal positioning systems used by most system integrators. 6-D Laser tackles this problem by integrating ultrafast laser material processing with the 6-D nanometer-level precision motion control solutions in which ALIO Industries specializes.

At the heart of 6-D Laser's integrated ultrafast laser micromachining system is ALIO Industries' Hybrid Hexapod, which takes a different approach to traditional 6 degree of freedom positioning devices. Rather than six independent legs (and 12 connection joints) ALIO's approach combines a precision XY monolithic stage, tripod and continuous rotation theta-Z axis to provide superior overall performance.

The combination of serial and parallel kinematics at the heart of ALIO's 6-D Nano Precision is characterized by orders-of-magnitude improvements (when compared to traditional hexapods) in precision, path performance, speed and stiffness. The Hybrid Hexapod also has a larger work envelope than traditional hexapods with virtually unlimited XY travel and fully programmable tool center point locations. The Hybrid Hexapod has less than 100 nm Point Precision repeatability, in 3D space.

6D Laser vertically integrates all of the subsystems required for precision laser microprocessing, and it does this by forming strategic partnerships with key component and subsystem suppliers that are required to achieve the goals of demanding precision applications. In addition to its association with ALIO, 6-D Laser has also partnered with Scanlab GmbH, which together with ACS Motion Control, has developed an unlimited field-of-view (UFOV) scanning solution for coordinate motion control of the galvo scanner and positioning stages called XLSCAN. 6-D Laser has also partnered with NextScanTechnology to provide high-throughput scanning systems that take advantage of the high rep-rates available in ultrafast lasers, and Amplitude Laser, a key supplier of ultrafast laser systems for industrial applications.

Dr. Stephen R. Uhlhorn, CTO at 6-D Laser, said, "Introducing an integrated ultrafast laser micromachining system that combines the positioning capabilities of the Hybrid Hexapod, with high-speed optical scanning leads to a system that can process hard, transparent materials with wide-range taper angle control for the creation of high aspect ratio features in thick substrates, without limitations on the feature or field size."

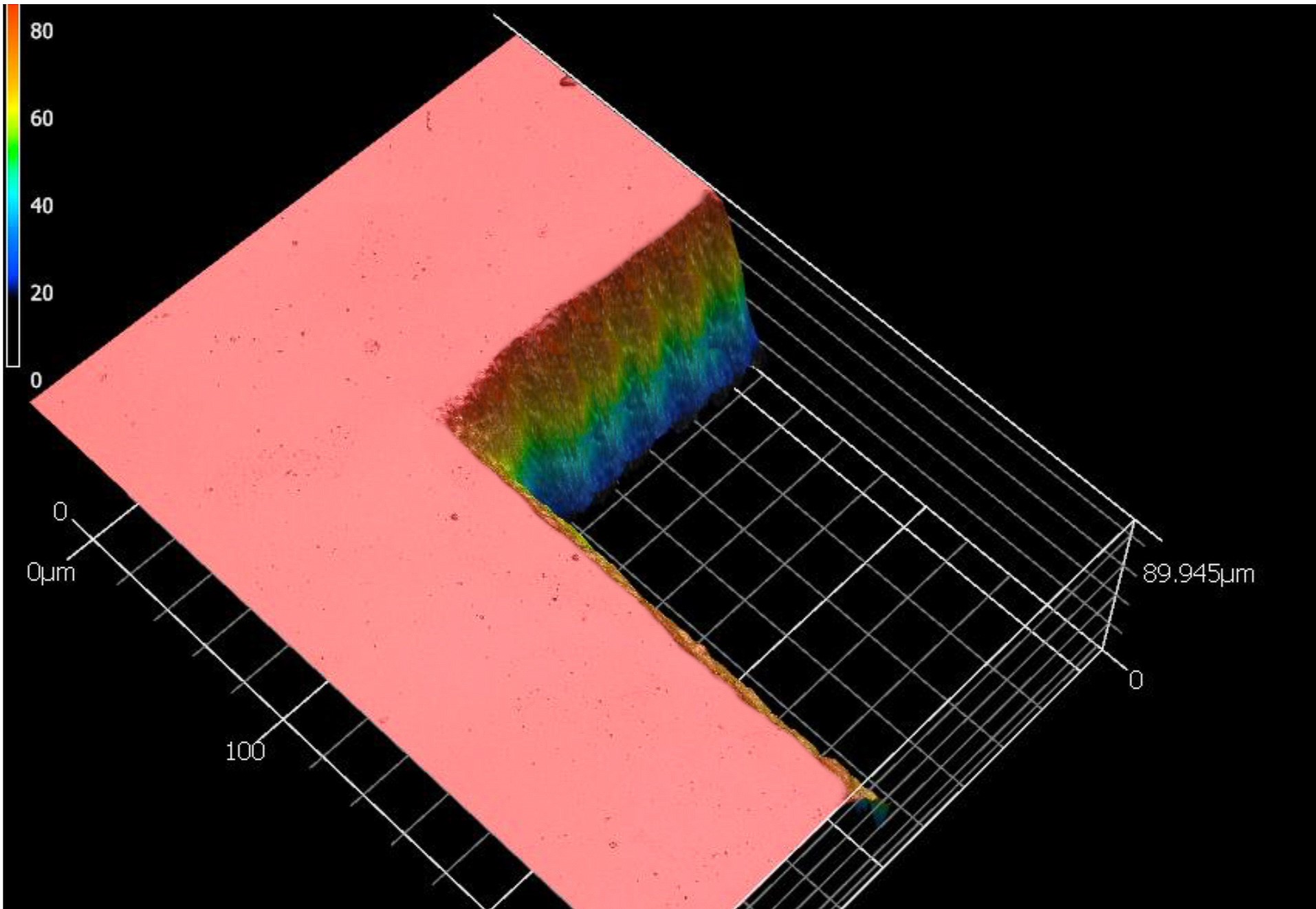

Ultrafast laser ablative processes, which remove material in a layer-by-layer process, result in machined features that have a significant side wall taper. For example, a desired cylindrical hole will have a conical profile. Taper formation is difficult to avoid in laser micromachining processes that are creating deep features (>100 microns). Precision scanheads can create features with near-zero angle side walls, but they are limited to small angles of incidence (AOI) and small field sizes by the optics in the beamline.

Uhlhorn added, "6-D Laser's micromachining system controls the AOI and resulting wall taper angle through the Hybrid Hexapod motion system, and the programmable tool center point allows for the control of the AOI over the entire galvo scan field, enabling the processing of large features."