Aluminum Alloy Growth Reflects Expanding Applications

Aluminum Alloy Growth Reflects Expanding Applications

New aluminum alloys can pose machining challenges, but they can be mastered with sound cutting strategies.

The difference between 75 and 531 speaks volumes about the development of aluminum alloys and the growing array of products made of those workpiece materials. When the Aluminum Association began managing the aluminum alloy designation system in 1954, the list of alloys included 75 unique chemical compositions. The list now includes 531 registered alloys and counting.

"We continue to see five to 10 alloys registered each year," said John Weritz, vice president of standards and technology for the association, which manages the registration process as an ANSI-accredited standards-setting body in collaboration with its member-companies.

He added that most new aluminum alloys are in the 2000, 6000 and 7000 series. These heat-treatable alloys have a relatively high strength while retaining aluminum's lightweight properties and are popular in aerospace and automotive applications.

Manufacturers also use the highly reflective, oxidation-resistant metal in a host of other applications, from sporting goods to jewelry. For example, Matt Meenan, director of communications for the Aluminum Association, pointed out that the casing of Apple's new watch is made of a 7000 series alloy. "In the tech industry, it's a relatively small amount of metal but it's a great showcase for the attractive, corrosion resistant and lightweight properties of aluminum," he said.

For an alloy to be considered aluminum, the majority of the metal must be aluminum, with other elements added to enhance its physical properties—often to increase the metal's strength. Alloying elements can include iron, silicon, copper, magnesium, manganese, titanium, zirconium and zinc at levels that, when combined, may make up as much as 15 percent of the alloy by weight, the association stated.

Also, lithium has emerged as an element for producing lightweight yet strong alloys. Weritz explained that NASA incorporated the newer-generation aluminum-lithium alloys to reduce the weight of the Space Shuttle's external fuel tank by 7,000 lbs. (3,175 kg), and this weight reduction was a critical design element that helped enable the construction of the International Space Station.

One producer of these alloys is Constellium, based in The Netherlands. Its Airware brand aluminum-lithium alloys are primarily for aerospace applications. For example, Airware 2050 is extensively machined to produce wing ribs for the Airbus A350 airplane, noted Michael Niedzinski, director of standardization, aerospace transportation for Constellium, who is based in Hoffman Estates, Ill. He added that aluminum-lithium alloys provide high strength and resist crack propagation, enabling manufacturers to produce parts with thinner walls and other features to significantly reduce component weight.

Niedzinski noted about 99 percent of these alloys contain 1 to 1.75 percent lithium, with most hugging the bottom of that range, along with a cocktail of eight to 10 alloying elements.

When determining the existence of a new alloy, the Aluminum Association's Weritz said a minor chemical composition alteration would indicate a variation of an existing alloy and would be designated as something similar. "If it's more than a mild tweak, we would give it a brand-new alloy designation."

Millstar offers a new line of indexable-insert cutters for milling aluminum. Image courtesy Millstar.

For instance, aluminum producers developed, in the last decade, the aluminum-lithium alloys 2295 and 2395, which are derivatives of the older 2195, Niedzinski said. "I expect that aluminum companies will continue to develop new products for new applications or come up with new solutions."

Nonetheless, that development work can't just take place in an R&D lab. For the association to register an alloy as new, it must first be produced and sold in commercial quantities, Weritz said. The definition of commercial quantity, however, is a gray area, because it depends on the product form. "Commercial quantity could be anything from a few thousand pounds to a few million pounds," he added.

Although the influx of new alloys might seem daunting for part manufacturers, the newer registrations have primarily been for teal sheets and wrought chemical compositions to enhance formability, and the cast compositions that are machined haven't seen developments as significant, according to Weritz. "If you have experience machining one 6000 series alloy, I doubt you'll see a massive change when machining a different 6000 series alloy."

If it Ain't Broke …

Therefore, the tried-and-true aluminum alloys continue to do the job for multiple applications, and toolmakers have enhanced their offerings to more effectively machine a metal that's generally considered easy to cut. One such offering is a new line of indexable-insert cutters for milling aluminum from Millstar, Orion Township, Mich. Vice President Ron Field said one industry the cutting tools are targeting is moldmaking, which has seen an increase in the production of 6061 and 7075 aluminum plastic-injection molds. An aluminum mold won't last as long as a steel one, but it's easier and cheaper to machine and offers better heat conductivity for water lines, so the molded parts cool quickly and cycle times can be reduced.

"An aluminum mold is not going to run millions of parts like some of the steel ones will," Field said, "but if it's producing enough parts, the end user is happy."

He explained that the Millstar endmills and shell mills for cutting aluminum are made with a fine-grain carbide with a low cobalt content so the substrate provides enhanced hardness and wear resistance. Also, the flutes are polished to make them as slippery as possible and minimize aluminum's tendency to stick to their surfaces, while an upsharp chipbreaker improves chip flow.

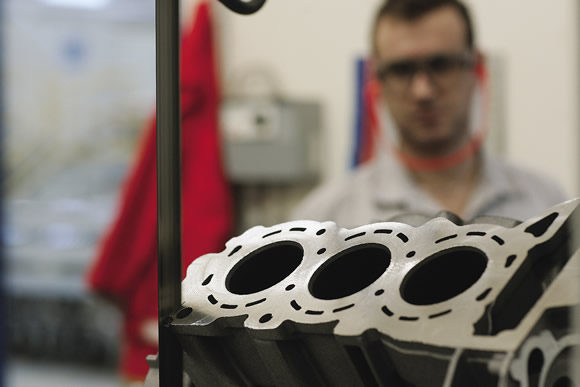

Automotive applications, such as this V6 engine block, are a main mover for the development of new aluminum alloys. Image courtesy Hydro.

To efficiently cut aluminum with the tools, Field recommends a spindle speed of at least 10,000 rpm and high-pressure, through-spindle coolant. However, the tools are also effective when dry machining. For instance, in a demonstration of a Millstar shell mill cutting 6061 aluminum on a Hurco VMX42HSi milling machine without coolant, the tool ran at 18,000 rpm, a feed rate of 1,134 ipm (28.8 m/min.), a DOC of 0.05 " (1.27mm) and a step-over of 1.75 " (44.45mm).

According to Field, the indexable inserts not only make quick work of roughing and finishing aluminum, they last a long time while doing it. "I have a customer who has been using the same insert for 24 hours a day, 7 days a week for probably 3 months," he said, noting the application is in 6061 aluminum, which is easy to machine.

Resisting Abrasion

Other aluminum alloys are not as easy to cut. Although a large, high-volume manufacturer might fine-tune its assortment of cutting tool grades for a specific chemical composition, a small to medium-size machine shop simply wants to know the silicon content, noted Don Graham, manager of education and technical services for Seco Tools LLC, Troy, Mich. "If it's more than 6 percent, they want to know how much more," he said, noting a content that's considered high starts there. "Then they begin to think diamond tools and diamond coatings."

This is because while high silicon content enhances a part's abrasion resistance, it also makes the workpiece material more difficult to machine by increasing the abrasiveness, he explained. HSS and carbide cutters can experience short tool life when cutting an abrasive aluminum alloy, whereas diamond, whether in the form of a PCD tool or a CVD diamond coating, has the high hardness to handle high silicon content.

Robert Quinn, machine shop manager for LA Aluminum Casting Co., Hayden, Idaho, concurred that machining aluminum alloys with high silicon content, such as 359.0 with 9 percent silicon, is hard on cutting tools.

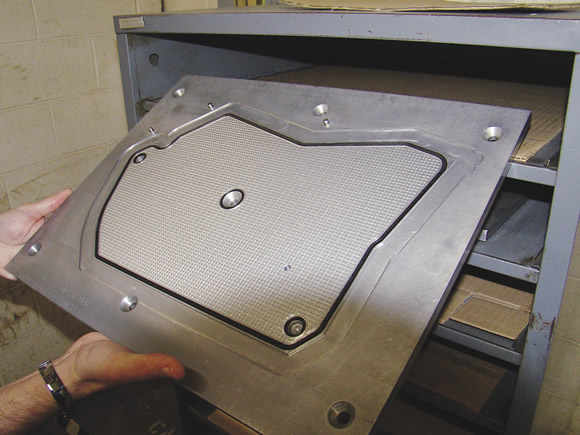

An aluminum top plate for a vacuum fixtures at AT Precision accommodates a specific part shape. Image courtesy A. Richter.

At LA Aluminum, a permanent mold aluminum foundry, castings go from the heat-treat process to the machine shop. Quinn noted the shop generally roughs castings with carbide tools that cost $20 to $25 each and finishes them with PCD tools that cost more than $100 each but last 10 times as long as carbide cutters and provide freer cutting. "PCD for the finish cut naturally gives a better finish," he said.

Quinn added that although a part might have a 32-rms finish specification, the shop frequently imparts a finish as fine as 16 rms when applying a PCD tool. "We're exceeding what we need to do but do it to hold the tolerance," he said.

According to Graham, diamond is also effective when machining aluminum alloys that form hard particles in their structure during heat treatment. This structure provides hardness and strength but decreases machinability, a major consideration, for example, when turning the vast majority of a workpiece into chips to reduce component weight and relieve internal stress.

"Those materials are favored by the aerospace industry, which talks a lot about the buy-to-fly ratio," he said. "A lot of aluminum gets machined and, therefore, you would like a tool that lasts a long time, and that means diamond."

However, not all diamond is the same. A cutting tool comprised of fine-grain diamond imparts a finer surface finish and exhibits more edge toughness than one coated with coarse-grain diamond, which enhances abrasion resistance and extends tool life, Graham pointed out.

While the particles that form during heat treatment can be harder than carbide and abrade cutting edges, according to Graham, the overall hardened workpiece can still be efficiently machined with standard high-performance cutting tools and does not require grinding because it does not have a high tensile strength. The maximum tensile strength is around 60,000 psi for a high-strength aluminum alloy, while a soft steel has an equivalent tensile strength, he added.

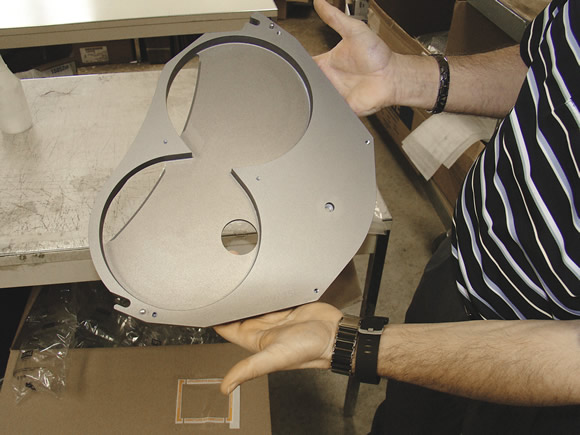

After machining, this feeder pan produced at AT Precision was anodized with Teflon. Image courtesy A. Richter.

Tool geometry also plays a significant role when tackling difficult alloys. Graham noted more end users are applying negative milling cutters that accept inserts with a positive cutting action. This allows them to aggressively run the cutters because the insert's free-cutting edge minimizes cutting force.

In addition, Constellium's Niedzinski emphasized that two important material attributes for machine shops is an alloy's ability to generate short, brittle chips to extend tool life and to remain stable when cut. "During machining, if there are internal stresses, a plate will have a tendency to move up and down on the machining bed," he said.

As the number of aluminum alloys increases, primarily driven by automotive and aerospace applications, Graham sees a trend towards stronger yet more abrasive offerings that put more pressure on the cutting edge. "I don't see them getting easier to machine," he said.

However, not only does one aluminum alloy compete with other aluminum products when the application is appropriate, aluminum competes with other metals, Niedzinski explained. For automotive parts, the main competition is high-strength, low-alloy steels, while aluminum competes with composite materials in the aerospace industry and with magnesium for small, high-value components. "It's a continuous battle, and the loyalty of the customer is minimal," he said, noting the only loyalty is based on the investment in tooling, such as dies. "If our product is not competitive, we will go through a major effort to develop an alternative."

Flapjack Condiment

A look at other applications for newer aluminum alloys reveals workpiece materials that enable high-speed metal removal with standard carbide tools. One example occurs at AT Precision Inc., Northbrook, Ill., which machines aluminum for about half its jobs. Although its list of aluminum alloys includes 6061-T6, 2024 and 7075, the main aluminum workpiece at AT Precision is Alcoa's MIC6, which the shop typically uses to make feeder pans for the pharmaceutical industry, noted President Chuck Thudium. He added that the shop reverse engineers all the feeder pans using sample parts.

According to Alcoa, the aluminum cast plate is a blend of the desirable features of many individual metals and is produced via continuous casting. Fully stress-relieved, the free-cutting aluminum alloy produces small, uniform chips when machined. "Compared to some of the other stuff, it cuts like butter," Thudium said.

AT Precision cuts the cast plates on 20-hp Haas milling machines with 15,000-rpm spindles and applies general-purpose, water-soluble coolant. The carbide cutting tools for machining aluminum are often uncoated, but Thudium noted TiN-coated tools help prevent aluminum from galling. When a part requires an 8- to 10-rms surface finish, AT Precision applies PCD-tipped inserts, followed by manual polishing to clean cutter lines.

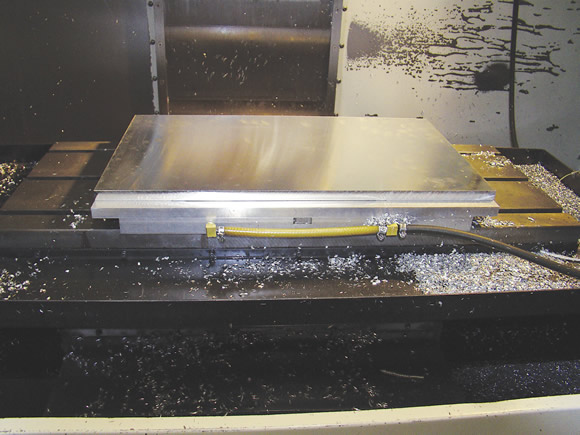

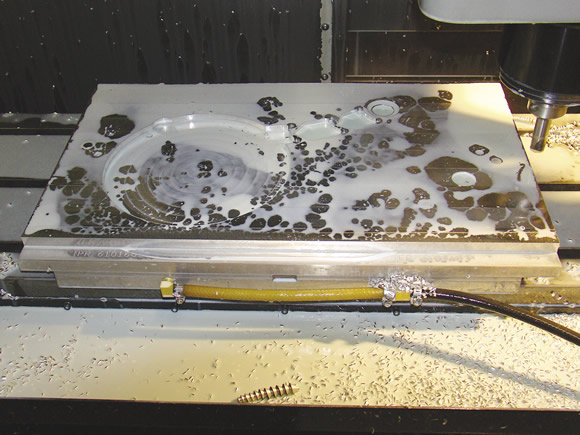

Thudium explained that instead of using workholding clamps, the shop produces vacuum fixtures in-house for holding plates to help minimize part distortion and access five sides of a plate. AT has used the fixtures since it first started machining aluminum (see sidebar on page 46). Each vacuum fixture has a base plate that remains on a particular machine and a top plate that accommodates the shape of the specific part being machined. The plates are changed and stored as needed. The base plates are usually made of MIC6 aluminum as well.

AT Precision machines MIC6 aluminum cast plates on vacuum fixtures it makes in-house to produce feeder pans for the pharmaceutical industry. Above is a workpiece prior to machining. Below is a partially machined workpiece covered with coolant. Images courtesy A. Richter.

The top plate provides a seal for the portion of the plate that's machined, and if a part requires a through-hole, for instance, a circular seal is positioned where the hole is drilled. "If you break the seal, there is nothing holding the part on the fixture and the part is going to go flying," Thudium said.

In addition to the pump for creating the suction, the vacuum system includes a water collector to remove coolant so it doesn't enter the pump.

After roughing aluminum parts, AT Precision sends them to a heat-treatment facility that soaks them in liquid nitrogen to stabilize the parts. "When the parts come back, they go on the same fixtures and we finish-machine them," Thudium said. "There is very little stress left in the material at that point."

Recycling on the Rise

As the number of registered aluminum alloys continues to rise, so does the percentage of aluminum that is recycled. The Aluminum Association's Meenan noted nearly 70 percent of U.S. aluminum production comes from recycled metal compared to about 30 percent in the 1980s.

"A piece of recycled aluminum takes about 8 percent of the energy needed to produce a piece of primary, or new, aluminum," he said. "So the more metal we can recover and recycle, the better it is economically and environmentally."

Regardless of whether the alloy comes from primary or recycled metal, Weritz added that it still has to meet the same chemical composition as the one that's registered with the Aluminum Association—today and tomorrow. CTE

About the Author: Alan Richter is editor of CTE. Contact him at (847) 714-0175 or [email protected].

Video supplement

For more information about Millstar's indexable-insert milling tools for machining aluminum, view a video presentation at www.ctemag.com by scanning the QR matrix code on your smartphone or entering this URL on your Web browser: cteplus.delivr.com/2gd5k

Contributors

Aluminum Association

(703) 358-2960

www.aluminum.org

AT Precision Inc.

(847) 509-5848

www.atprecision.com

Constellium

(847) 304-5593

www.constellium.com

LA Aluminum Casting Co.

(800) 635-8720

www.laaluminum.com

Millstar

(877) MILLSTAR

www.millstar.com

Seco Tools LLC

(800) 832-8326

www.secotools.com

Shop with a view

AT Precision Inc. is unique in a couple of ways. Not only is the machine shop located on the second floor of a building with a 12 " (304.8mm) concrete floor, but the company, which was founded in 1989, didn't have to machine a single part for one production job that involved machining aluminum parts.

President Chuck Thudium explained that in 1999 Greg Kaplan of K&C Machining Inc., Wood Dale, Ill., a friend with whom he would trade work back and forth, asked him to run some complex and expensive aluminum sample parts that had a 2-week turnaround for a customer. After AT Precision successfully completed them, the customer requested 6,000 more parts to be delivered in 6 months.

Chuck Thudium, president of AT Precision, and Chris Kaczowka, lead CNC machinist, monitor the production of a feeder pan in a Haas high-speed CNC milling machine. Image courtesy A. Richter.

"It was just impossible with that timetable," Thudium said, adding that even the combined capacity of the two shops wasn't sufficient to meet that demand. The customer persisted, so Thudium and Kaplan calculated the costs for all the tooling, workpiece materials, material handling equipment, the vacuum fixtures required for the project and the desired profit. In addition, they included the cost for each shop to lease 10 CNC mills and divided the total by 6,000.

The customer agreed and production was ready to begin within about a month. The project, however, came to screeching halt when the customer informed the shops that an FCC requirement prevented the part design from being used and it was too far off to correct. "We said, 'OK, but we are on the hook for a lot of money here. We have a guaranteed lease on these machines for 6 months,'" Thudium said.

Fortunately, there was a cancellation cost in the contract and Thudium and Kaplan received a check in 4 weeks that covered everything. "It got even better because another division of that particular company had a lot of parts they needed machined," Thudium said. "That worked out so well that after the 6-month lease, both of us bought all the machines. We just paid everything off and went forward."

—A. Richter