Ceratizit showcases portfolio at Southtec

Ceratizit showcases portfolio at Southtec

Ceratizit USA, in Warren, Michigan, exhibited at the Southtec trade show and showcased its full range cutting tools portfolio, including inch assortment, and hard materials solutions.nn

Ceratizit USA, in Warren, Michigan, exhibited at the Southtec trade show and showcased its full range cutting tools portfolio, including inch assortment, and hard materials solutions.

Ceratizit USA, in Warren, Michigan, exhibited at the Southtec trade show and showcased its full range cutting tools portfolio, including inch assortment, and hard materials solutions.

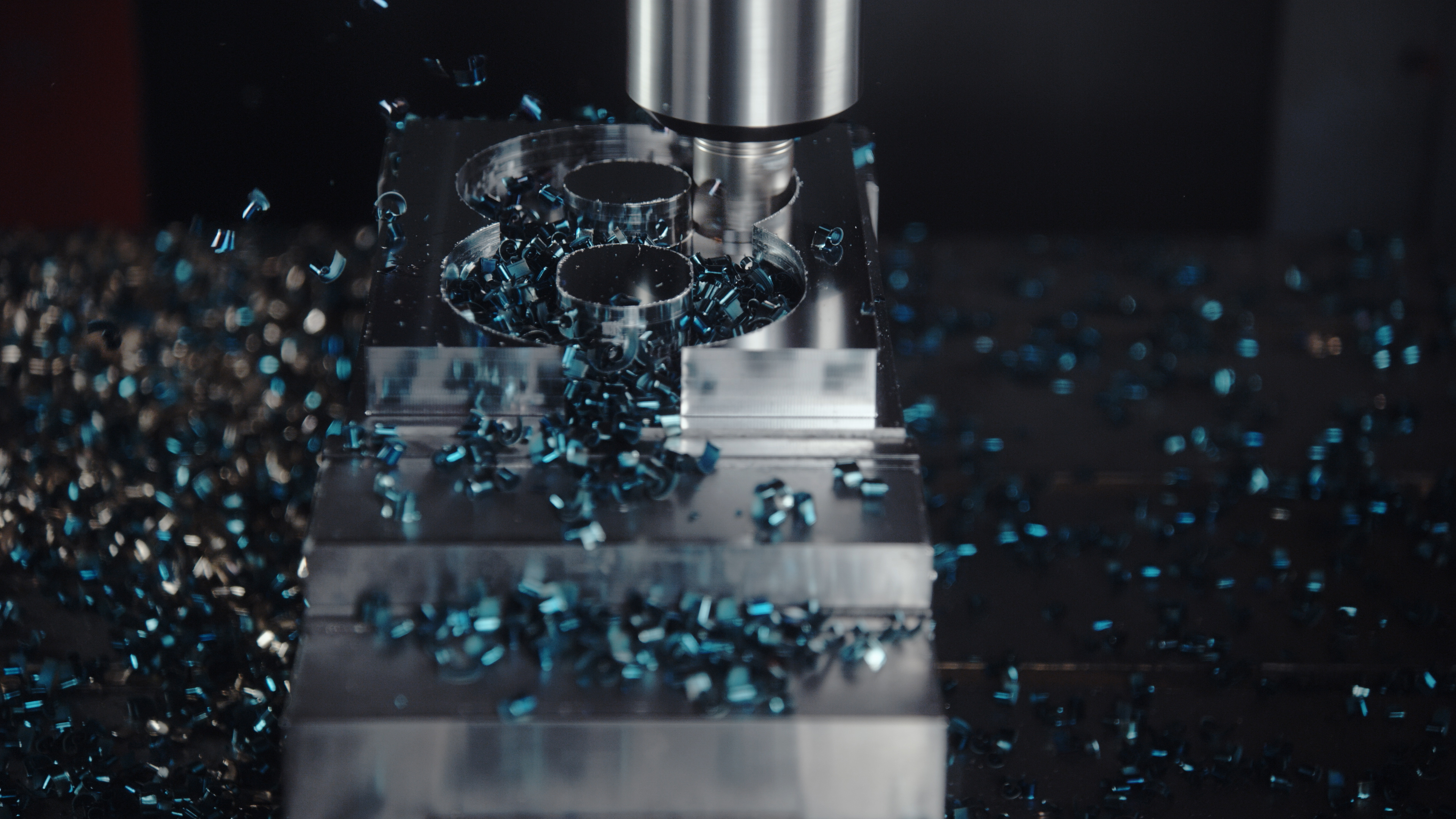

The company showcased its brands, including Cutting Solutions by Ceratizit, Komet, and WNT, and its premium turning tools, indexable and solid carbide milling, indexable and solid carbide drilling, and reamers, among others. For hard materials, Ceratizit displayed a range of solid carbide rods and preforms.

Highlights for hard materials include two new sustainable solutions, which includes the Exchangeable Head System (EHS) that offers maximum efficiency and economy with an exchangeable tool connection. The environmentally sound CTS20G end mill blanks incorporate a large concentration of high-quality secondary raw materials into a cutting tool grade and offer superb performance, the company says.

According to Andy Newbery, national sales manager for Rods and Wear Parts, "Ceratizit continues to bring top innovative and quality solutions to the market. Both the EHS and CTS20G are great options for customers who are looking for sustainable and quality without any compromise in performance."

According to Andy Newbery, national sales manager for Rods and Wear Parts, "Ceratizit continues to bring top innovative and quality solutions to the market. Both the EHS and CTS20G are great options for customers who are looking for sustainable and quality without any compromise in performance."

Innovative tooling

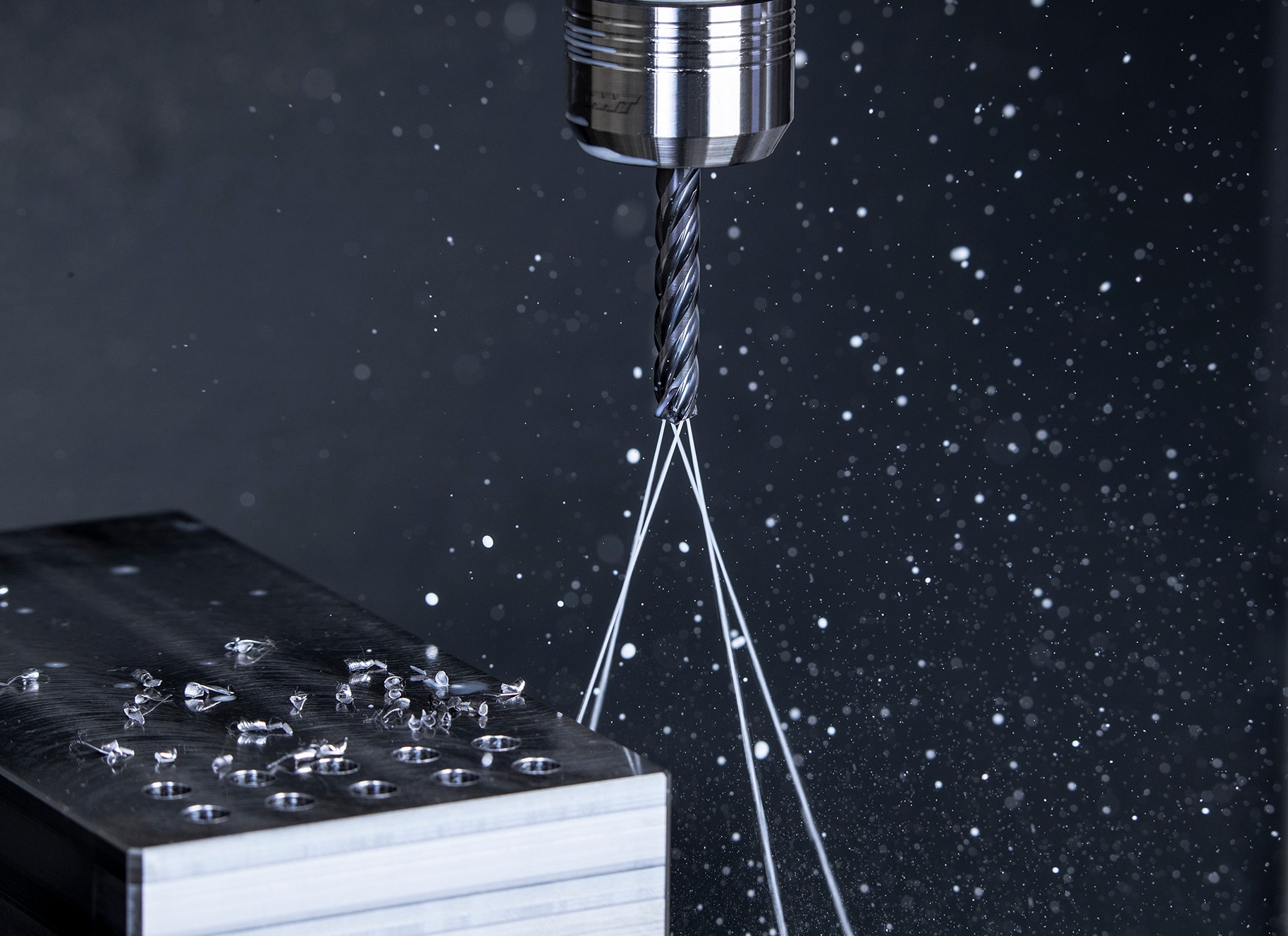

Cutting tools highlights included the WTX-HFDS solid carbide drill, which is the first four-flute drill on the market, according to the company. Coated with Ceratizit's proprietary Dragonskin coating, the drill achieves new levels of quality, hole tolerance, and positioning accuracy, with low burr formation while entering and exiting the hole. Additional tools included the CTPX710 and the CTPX715, the first multi-application insert grades from Ceratizit that machines steel, stainless steel, superalloys, and non-ferrous metals. Visitors also saw the KUB Quatron indexable drill, US-made solid carbide endmills, MaxiMill 491 indexable milling cutters, and FullMax high-performance reamers.