Kern Microtechnik GmbH establishes new location

Kern Microtechnik GmbH establishes new location

To better serve customers in Asia, Kern Microtechnik GmbH, Eschenlohe, Germany, set up a sales and service location in Shanghai called Kern Asia Pacific.

To better serve customers in Asia, Kern Microtechnik GmbH, Eschenlohe, Germany, set up a sales and service location in Shanghai called Kern Asia Pacific. From May 2018, the entire Asian market will be served from there.

In addition to Europe and the USA, many Asian countries are among the world's leading economies. In particular, the markets in China are in constant motion and manufacturers there are increasingly prioritizing high quality. Accordingly, the technology used to produce a wide range of goods is also subject to changing requirements. For example, the demand for high-precision machining centers — such as those manufactured by KERN Microtechnik — is constantly increasing. Following this trend, the precision engineering company has been delivering its milling centers to Asia for many years, primarily via the Swiss retailer DKSH, which has been strongly rooted in Asia since 1860.

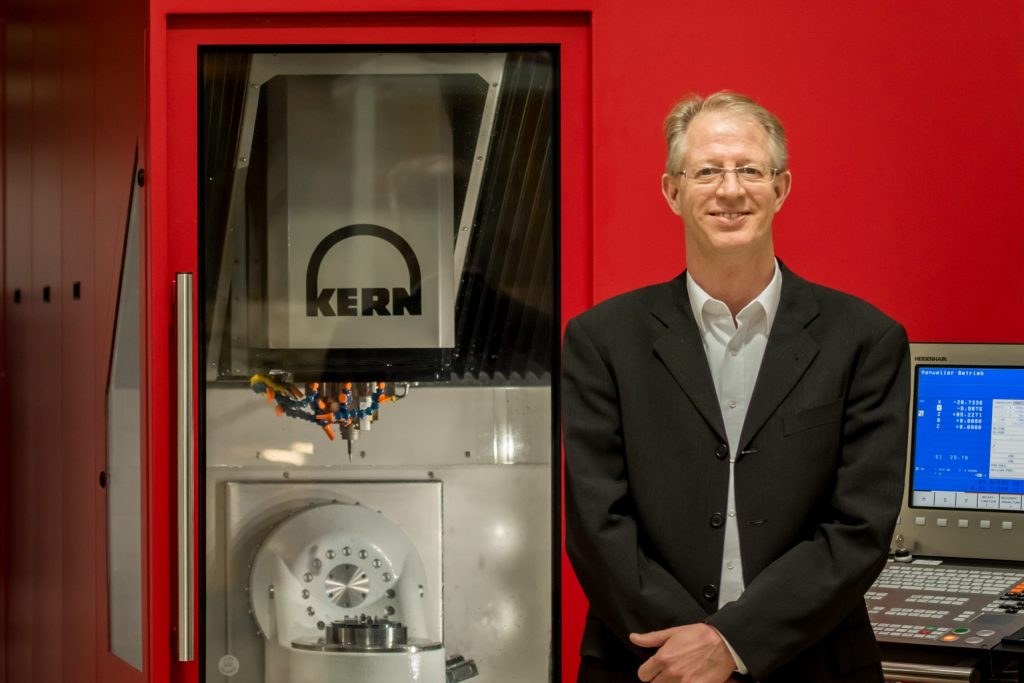

With the founding of the KAP sales and service center in Shanghai in May 2018, KERN is now going one step further in terms of providing customer support in Asia. In close cooperation with DKSH and under the direction of KERN Asia's regional sales manager, Udo Reinwald, seven highly qualified Chinese sales consultants will serve their home market. In addition, two Chinese service technicians, who have received extensive additional training at KERN in Germany, will look after KERN's existing customers in the region. Similarly, well-trained sales and service technicians will also be on hand to support customers in India, Singapore and Malaysia.

To ensure it can carry out maintenance work and repairs promptly, the German precision machinery manufacturer has also established a free-trade warehouse for spare parts. As a result, all relevant, high-quality components are kept in stock and can usually be delivered to customers within one day. KERN service technicians, who are equipped with special tools, are therefore able to carry out any necessary work within a short time frame.

For Udo Reinwald, these steps are crucial for his company's continued success in Asia, as he explains: "We need to be close to our customers wherever they are. That's why we have locations in Europe, the US and now also in Asia. In this way, we can always respond quickly to sales and service issues and at the same time get to know the needs of the region."

Because KERN consistently works with local experts, communication takes place in the local language. Problems can thus be quickly understood and remedied without delay. In addition, the company's service technicians are able to identify customer requirements and forward them directly to the developers at KERN headquarters in Germany. Using this information, machines and accessories can then be specifically developed for the Asian market. This helps the company to achieve healthy growth, thereby safeguarding existing jobs as well as creating new ones.