MSC Industrial acquires two cutting tool firms

MSC Industrial acquires two cutting tool firms

MSC Industrial Supply Co., a distributor of Metalworking and Maintenance, Repair and Operations supplies to industrial customers throughout North America, has acquired ApTex Inc. and Premier Tool Grinding Inc.

MSC Industrial Supply Co., a distributor of Metalworking and Maintenance, Repair and Operations supplies to industrial customers throughout North America, has acquired ApTex Inc. and Premier Tool Grinding Inc.

Under the purchase agreements, both companies will continue to operate under their current names as MSC companies. Combined, the two companies had estimated revenues of slightly over $20 million in 2023 and have 58 associates. Both acquisitions are expected to be net neutral to MSC's fiscal year 2024 net income.

ApTex, based in Waukesha, Wisconsin, is a production-oriented industrial distributor with a focus on cutting tools, abrasives, metalworking fluids, as well as workholding systems and components. ApTex is a highly technical metalworking distributor with a focus on value-added services and solutions to drive cost savings through every step of the customers' production process.

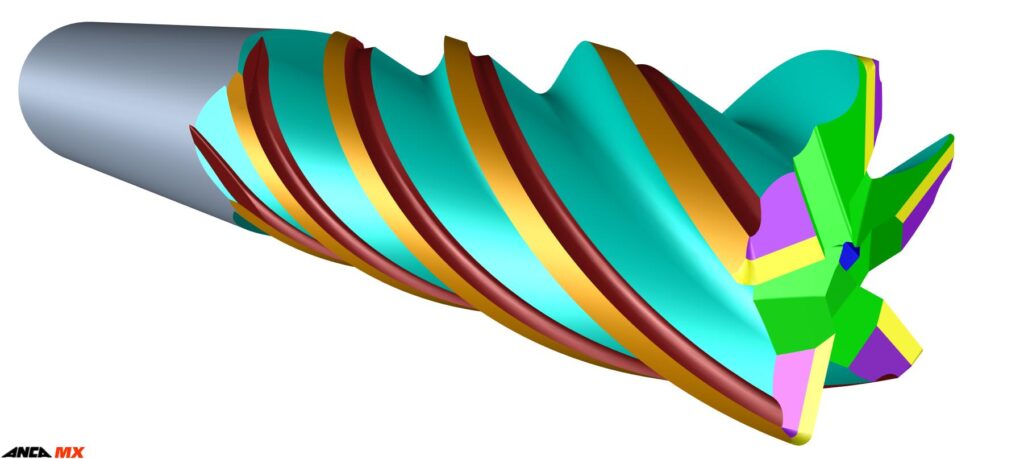

Premier Tool Grinding designs, manufactures, reconditions, and coats carbide cutting tools. Located in Goodyear, Arizona, the company has made significant strides over the years, transitioning from manual grinding machines in its early beginning in 1991 to a fully automated shop equipped with CNC machines and state-of-the-art PVD coating machines.

MSC President and Chief Executive Officer Erik Gershwind said, "We are thrilled to welcome ApTex and Premier Tool Grinding into the MSC family. ApTex will strengthen our position to gain share in the surrounding Wisconsin area by combining ApTex's deep technical expertise with MSC's best-in-class metalworking offering. Additionally, Premier Tool Grinding will bolster MSC's specialty tooling and regrinding service offering that was recently enhanced through the acquisition of Tru-Edge and expands our reach to western parts of the U.S."

Dean Meier, President of ApTex, said, "As we join the MSC family, we look forward to combining our technical expertise and solution-driven approach with MSC's expanded product offering to drive further cost savings for customers."

"Joining forces with MSC represents a significant milestone for us. It's an opportunity to leverage our innovative spirit and technical prowess on a larger scale. We are excited to contribute to MSC's legacy of excellence and to continue delivering unparalleled solutions to our customers," said Shaun Schilling, Co-Owner of Premier Tool Grinding.