NIST, partners create mfg. standards

NIST, partners create mfg. standards

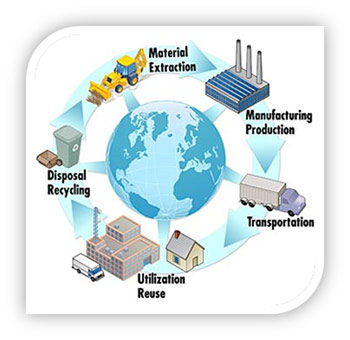

According to the U.S. Energy Information Administration, manufacturing accounts for one-fifth of the annual energy consumption in the United States—approximately 21 quintillion joules (20 quadrillion BTU) or equivalent to 3.6 billion barrels of crude oil. To reduce this staggering amount and improve sustainability, manufacturers need to accurately measure and evaluate consumption of energy and materials, as well as environmental impacts, at each step in the life cycles of their products.

According to the U.S. Energy Information Administration, manufacturing accounts for one-fifth of the annual energy consumption in the United States—approximately 21 quintillion joules (20 quadrillion BTU) or equivalent to 3.6 billion barrels of crude oil. To reduce this staggering amount and improve sustainability, manufacturers need to accurately measure and evaluate consumption of energy and materials, as well as environmental impacts, at each step in the life cycles of their products.

However, making these assessments can be difficult, costly and time consuming, as many manufactured items are created in multiple and/or complex processes, and the environmental impacts of these processes can vary widely depending on how and where the manufacturing occurs. Additionally, the data collected are often unreliable, frequently not derived through scientific methods, and do not compare well with those from other types of manufacturing processes or from processes at different locations.

These issues are beginning to be addressed through a recently approved ASTM International standard for characterizing the environmental aspects of manufacturing processes (ASTM E3012-16). The guide provides manufacturers with a science-based, systematic approach to capture and describe information about the environmental aspects for any production process or group of processes, and then use that data to make informed decisions on improvements. The standard is easily individualized for a company's specific needs.

Read more at http://www.nist.gov/el/nist-partners-create-standard-to-improve-sustainable-manufacturing.cfm.