REGO-FIX USA celebrates IndyDays during its Center for Machining Excellence open house

REGO-FIX USA celebrates IndyDays during its Center for Machining Excellence open house

REGO-FIX USA plans to celebrate the month of May and the Indianapolis 500 with its Center for Machining Excellence (CME) inaugural open house May 14 – 15 in Whitestown, Indiana.

REGO-FIX USA plans to celebrate the month of May and the Indianapolis 500 with its Center for Machining Excellence (CME) inaugural open house May 14 – 15 in Whitestown, Indiana.

The Indy Days: Race Into Excellence event will run from 9 a.m. to 6 p.m. (EST) daily and feature the latest advances in manufacturing technology from REGO-FIX and its CME partners from around the world. The center provides a welcome environment for collaboration involving all part machining processes.

More than two dozen global REGO-FIX CME partners are slated to attend the event with state-of-the-art technology exhibits, machine demonstrations and best practices guidance designed to help customers improve their processes and meet their manufacturing challenges.

To date, participating companies, include: Blaser Swisslube; Blum; Bruker Alicona; Brutsch Ruegger Tools; Diametal; Fraisa; Greenleaf; Heidenhain; HWR; HyperMill; IMCO; JKS America; Kern; Kitamura; Star SU | Louis Belet; M.A. Ford; Mikron Tool; Mitsubishi Materials U.S.A.; OMEGA TMM; RobbJack; Sharon Cutwell; SolidCam; Tornos; Triag; Utilis-GenSwiss; and Way of the Mill.

While experiencing world-class manufacturing solutions, attendees can keep abreast of all the action at Indianapolis Motor Speedway with a live simulcast of NTT IndyCar Series practice for the 109th Running of the Indianapolis 500.

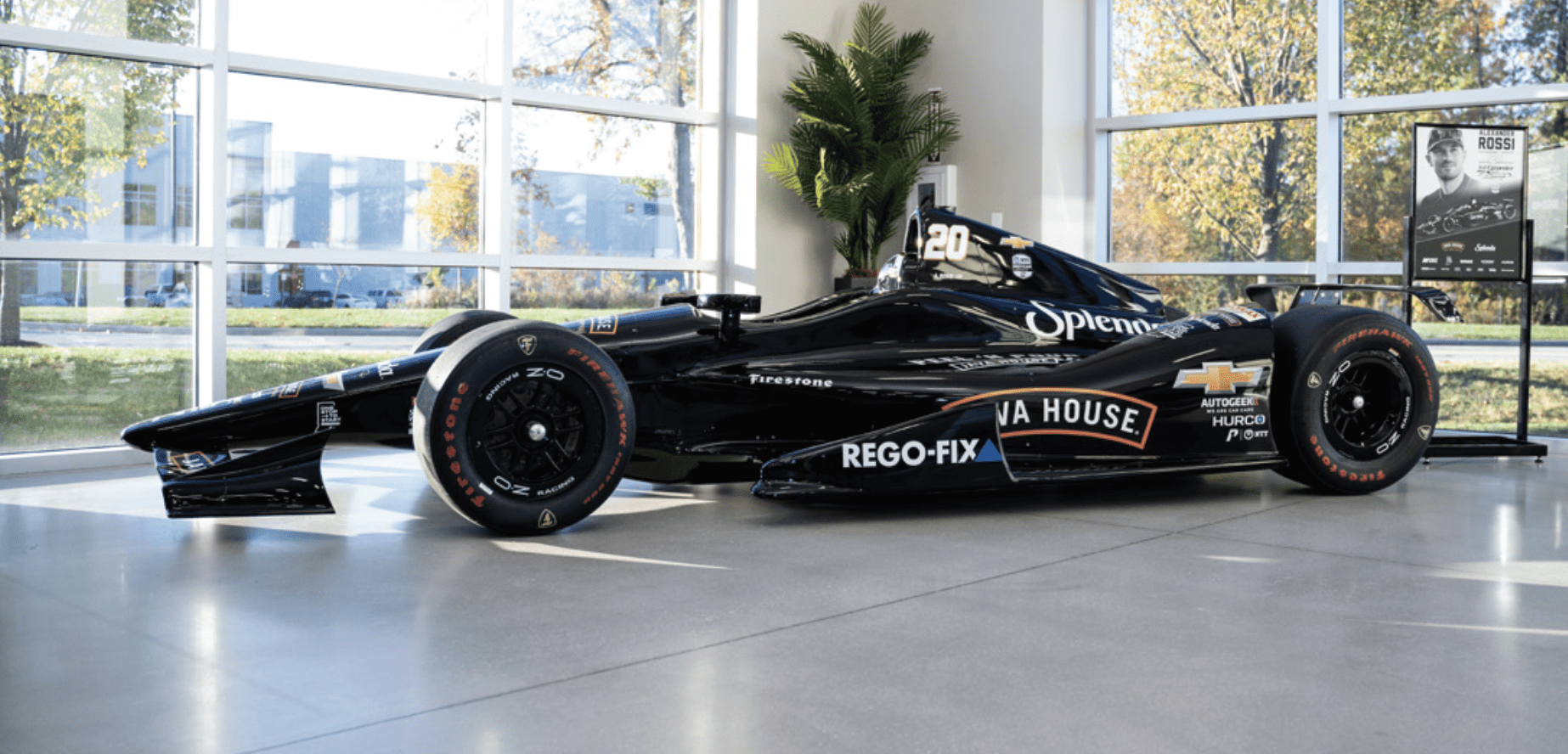

As a special guest, Indianapolis-based IndyCar Series ECR racing team will exhibit at the event. REGO-FIX joined forces with ECR – helmed by owner/driver Ed Carpenter – last May as the premium toolholding solutions provider for the team's machine shop. ECR uses REGO-FIX's world-renowned ER collets and other related accessories, the powRgrip toolholding system and Multi Line products that boost the accuracy of traditional-style tooling for its precision parts machining.

Located adjacent to the company's U.S. headquarters in Whitestown, Indiana, just 30 minutes north of the Indianapolis Motor Speedway and Indianapolis International Airport, the CME opened in October 2024 and lies at the heart of North America's manufacturing corridor.

The state-of-the-art 12,000-square-foot manufacturing innovation and educational facility provides specialists in cutting tools, clamping systems, software, automation and metrology a prime opportunity to engage with customers, distribution partners and thought leaders who will be among the thousands of race fans who visit Central Indiana during the month of May.

For more information about the REGO-FIX CME open house, visit the Indy Days: Race into Excellence event page.