Star Cutter expands its PCD tool reconditioning services

Star Cutter expands its PCD tool reconditioning services

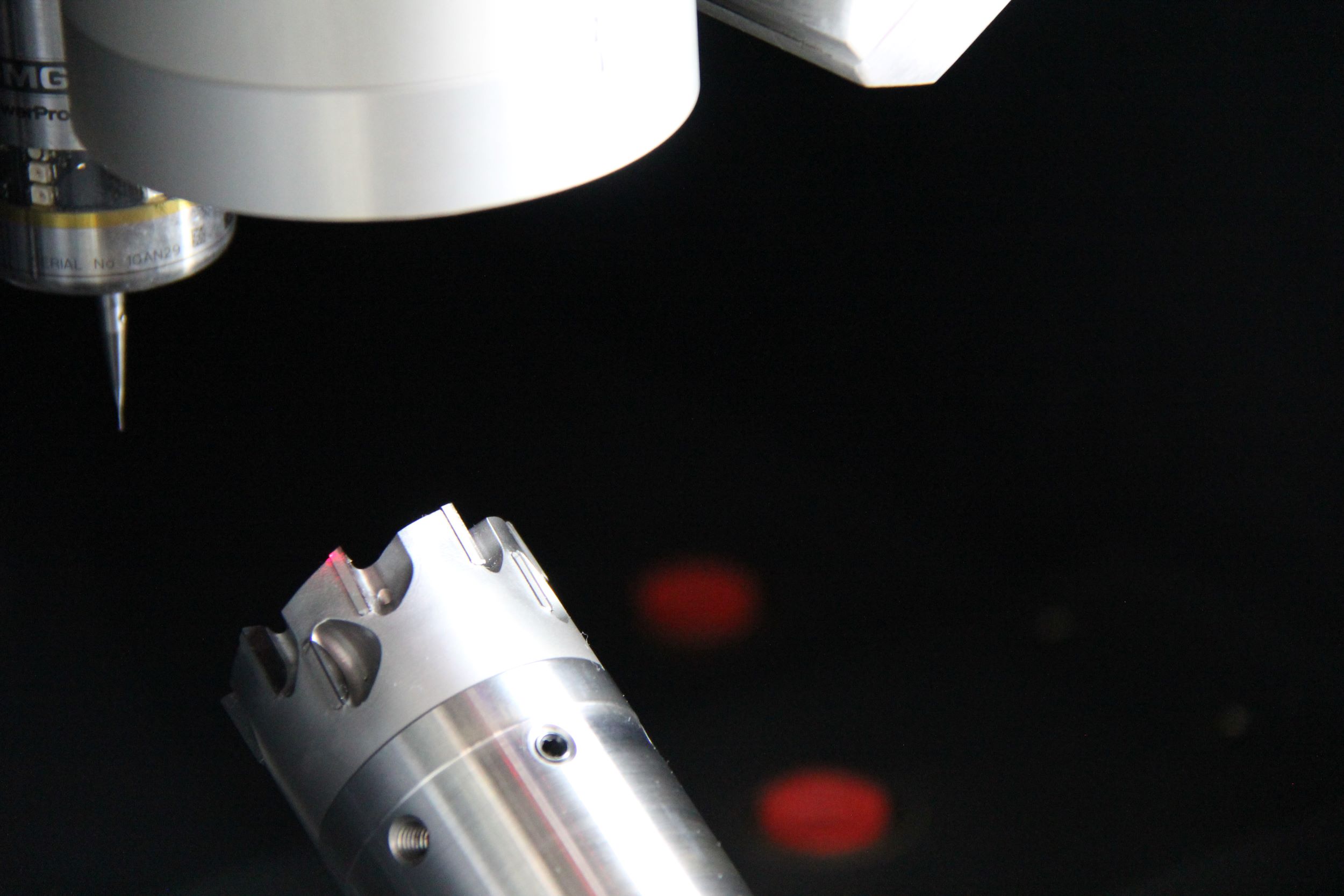

Star Cutter has added a Lasertec precision laser cutting machine to its portfolio of machining equipment at its Tool Reconditioning Center.

Star Cutter has added a Lasertec precision laser cutting machine to its portfolio of machining equipment at its Tool Reconditioning Center.

The machine enhances its ability to quickly restore PCD tools to their original condition, helping lower the cost of ownership over the life of the tool for its customers.

The Lasertec can handle highly complex tools, offering very fine cutting and the ability to address a smaller inside radius and sharper cutting edge on the PCD than EDM technology.

The laser machine also offers high repeatability and reproducibility with a positioning accuracy of ≤ 0.2032 μ. Additionally, there is less handling of the tool that has chip breakers as the lasered chip breakers can be machined in the same step and position as when the cutting edge is made, eliminating the need for a second clamping operation.

Star Cutter provides reconditioning for its own PCD products – 3D printed tools, circular mills, interpolating tools, facemills, combination tools, reamers and drills -- as well as other manufacturer's tools. The reconditioning center is equipped to repair these products to their original conditions.

For more information on PCD tool reconditioning, call (248) 474-8200 or email [email protected].