TCI Precision’s machine-ready blanks program

TCI Precision’s machine-ready blanks program

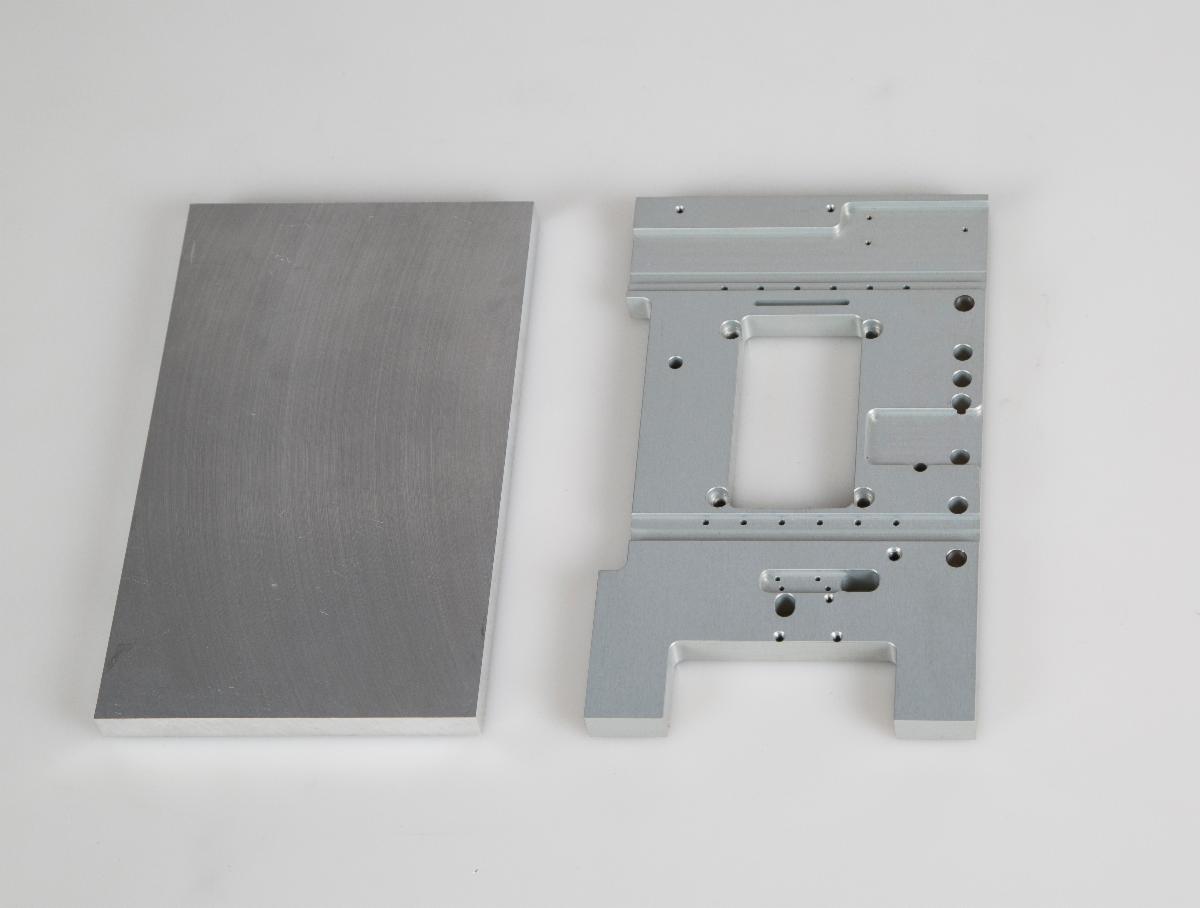

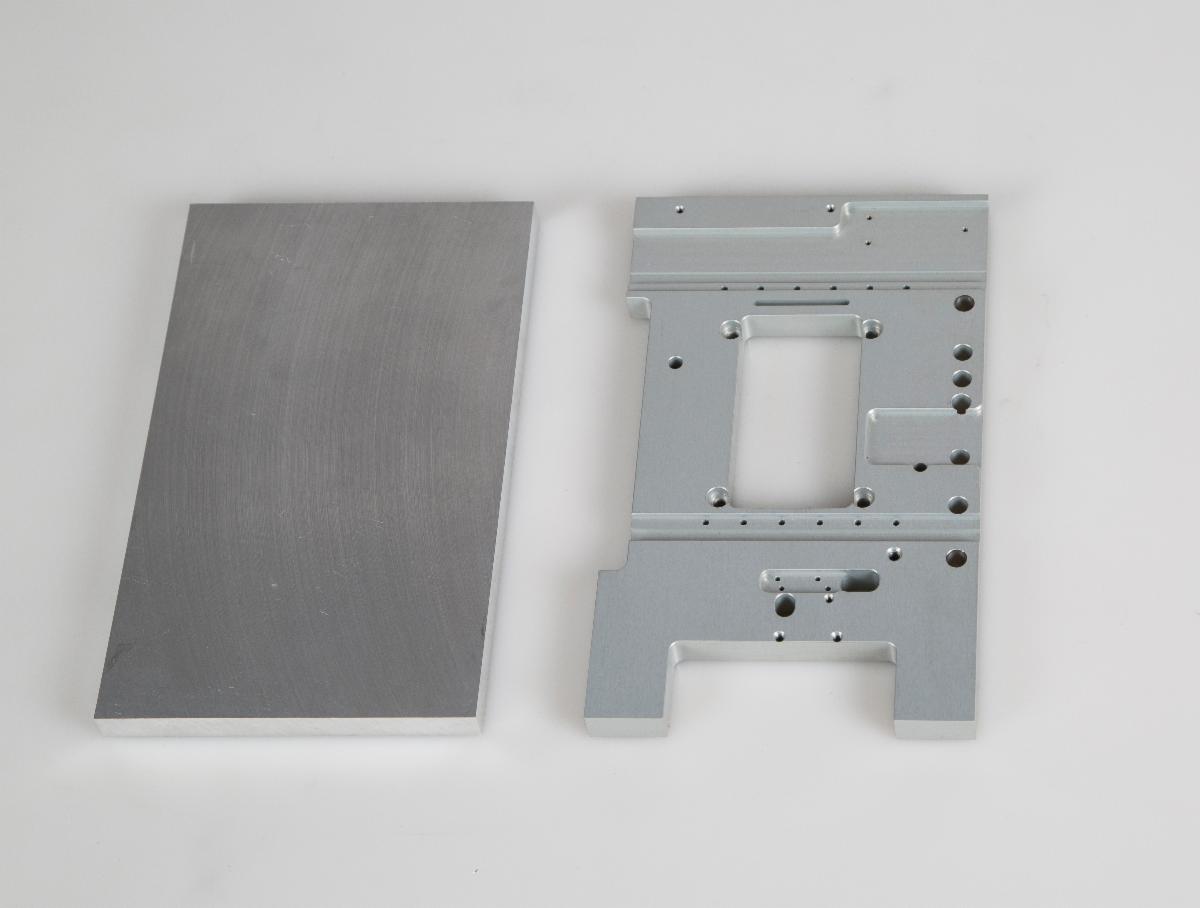

TCI Precision Metals launched a program to provide customers with first article sample parts on request with accompanying production volume quotation.

TCI Precision Metals launched a program to provide customers with first article sample parts on request with accompanying production volume quotation. The program allows customers to verify production processes, fixturing and create first article finished parts, realizing the benefits of machine-ready blanks, before ordering the materials.

TCI Precision Metals launched a program to provide customers with first article sample parts on request with accompanying production volume quotation. The program allows customers to verify production processes, fixturing and create first article finished parts, realizing the benefits of machine-ready blanks, before ordering the materials.

Founded in 1956, TCI Precision Metals is a family-owned precision manufacturer producing close tolerance machine-ready blanks from aluminum, stainless steel and other alloys.

Machine-ready blanks from TCI Precision Metals helps shops increase throughput up to 25% allowing them to ship finished parts faster and get paid quicker. With a single purchase order customers receive custom precision blanks ready to load directly into their CNC machining centers," said Ben Belzer, president and COO of TCI Precision Metals. "And with our just-in-time program we can ship the materials all at once or deliver it in batches based on the customer's production schedule."

Near net size precision blanks eliminate the need for in-house sawing, grinding, flattening, squaring operations and outside processing. Each blank arrives deburred, clean and to customer specifications that are guaranteed to meet tolerances as close as ±0.0005" dimensionally and depending on size as close as 0.001" flatness, squareness, and parallelism. When flat blanks are specified, the TCI Precision Metals production process elevates residual stress in the material, consistently producing close tolerance flat blanks that resist part movement during finish machining, improving overall quality.

"Our goal is to help customers be more productive and increase their shops capacity and throughput without adding overhead. Starting production jobs with precision machine-ready blanks is an easy way to gain immediate results. Our Free First Article Blanks program gives customers the ability to see, touch and work with the actual machine-ready materials as part of their pre-production process," said Belzer.

For more information on the ready-blanks program, phone 800-234-5613 or visit the company's website by clicking here.