Thomson adds encoder option to online selector tool for actuator

Thomson adds encoder option to online selector tool for actuator

Thomson Industries Inc., a manufacturer of linear motion control solutions, upgraded its stepper motor linear actuator (SMLA) online selector tool, adding the ability to include encoders in the design process.

Thomson Industries Inc., a manufacturer of linear motion control solutions, upgraded its stepper motor linear actuator (SMLA) online selector tool, adding the ability to include encoders in the design process.

The company said the new option streamlines the design and purchasing process for engineers and machine builders, making it even easier for them to weigh their options for incorporating position data into their designs.

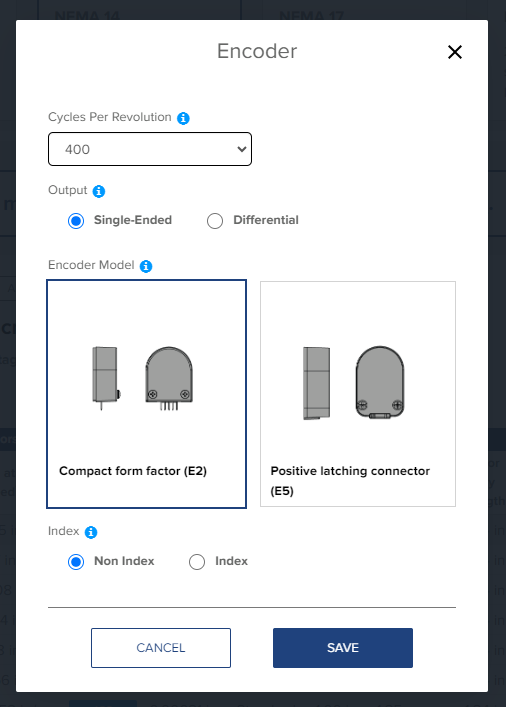

The Thomson selector tool automates selecting the right SMLA for machine design needs. According to the company, with a few intuitive steps, engineers can define motor frame size, screw, and nut configurations, and now they can also specify the exact encoder required for their application. Users can specify encoder cycles per revolution (CPR), non-index or index feedback control, or single-ended or differential output without leaving the online specification session. As users make their selections, the tool automatically updates the product specifications and provides real-time visualization, reflecting changes in the actuator's dimensions and design.

"This upgrade gives our customers the flexibility to choose the right motor and seamlessly integrate the entire assembly, including encoders, all in one interface. By automating what was previously a manual and time-consuming process, we have made it faster and more intuitive," said Lindsey Brimage, Sr. Product Manager for Screws at Thomson. "Now, with real-time updates and CAD model downloads, our customers can get exactly what they need, more efficiently than ever."