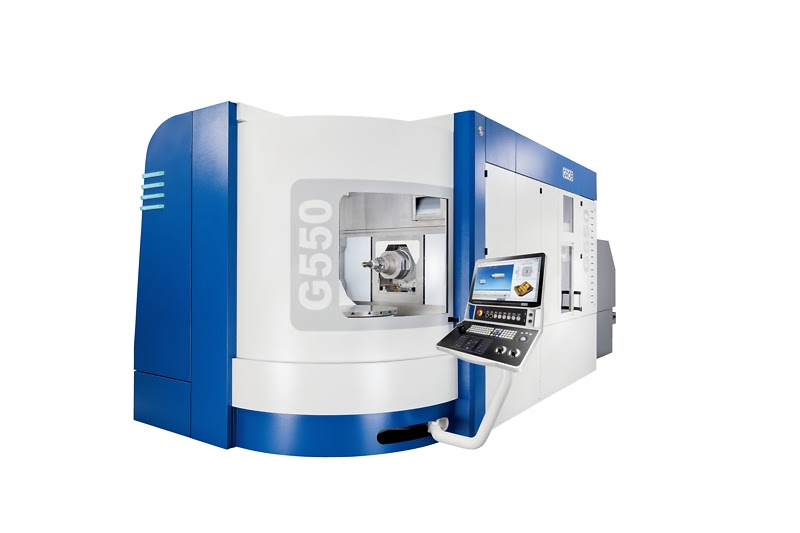

Interactive online event by Ceratizit happens June 17

The Ceratizit Group is hosting a global online event, "It's Tool Time," on June 17 to focus on the value of process optimization through a variety of interactive machining demonstrations and presentations.