Products

•

December 8, 2020

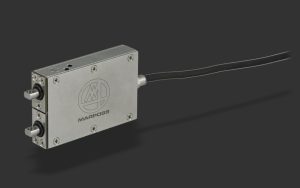

DX4 Servo drive and MX Servo Motor Series

The launch of the new DX4 servo drive and MX servo motor series expands Trio's machine solution and now makes it faster and easier for OEMs to utilize the high performance motion control available from Trio's range of Motion Coordinators. The DX4 servo drive has plug-and-play compatibility with Trio's controllers and slice I/O systems, all programmed within a single software, Motion Perfect 5. This increases the speed of application development and commissioning for OEMs in industries including packaging, medical, metal, CNC, robotics and 3C. The DX4 servo drive operates at 200V AC and power extends from 50W to 3kW.