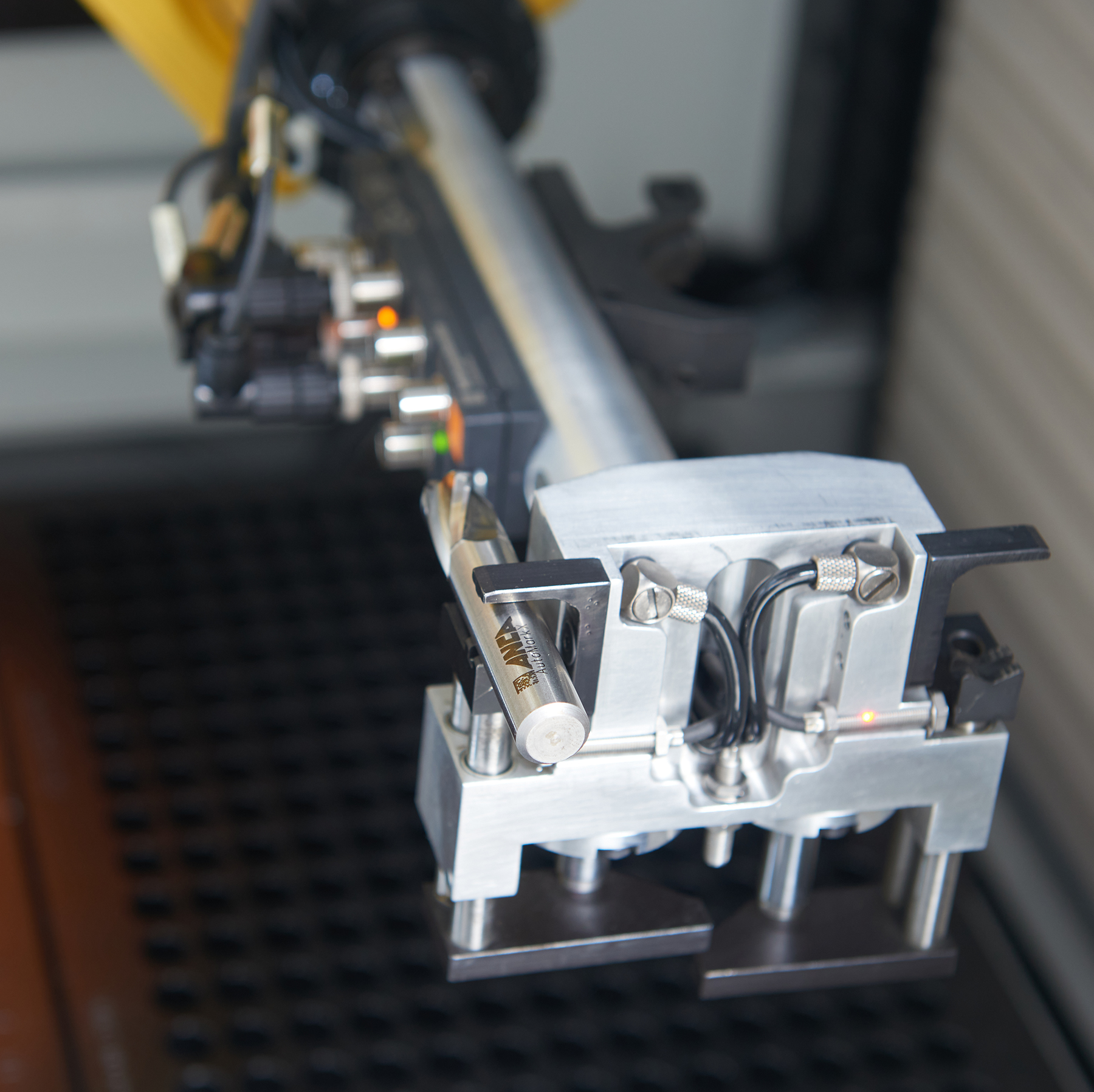

GSH 200A Thread Grinding Machine

The machine's capabilities include a 15 kW direct-drive motor that produces maximum wheel spindle speed of 6000 m/min. X-axis stroke of 330mm features a rapid feed rate of 5m/min, Z-axis stroke is 2150mm with 10m/min rapid feed, and maximum work spindle speed is 200 rpm.