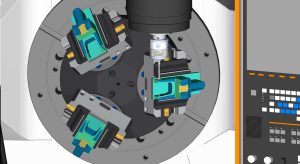

STC-MTV Five-Axis Mill-Turn Machining Centers

The two new machines, models MTV 1000 and MTV 1250 offering 8,000 rpm/700 ft lbs. of torque and 4,500 rpm/1,200 ft lbs. plus 200 bar/3,000 psi high pressure coolant for integrated turning, are joining the STC-MTV family of horizontal machining centers.