Wear mechanics of cylindrical grinding wheels

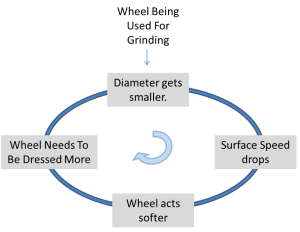

We all know that as grinding wheels wear and get smaller, they eventually stub out, requiring replacement. But what really happens as they wear? Does performance change? Do wheels act or behave differently as they wear? Do we need to change the grinding or dress parameters throughout whel life to compensate for these changes?