-scaled-300x200.jpg)

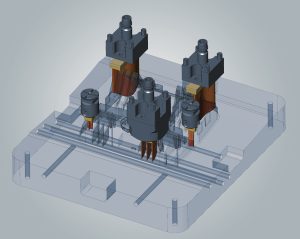

Two-station RXS-400 Grit Blasting System

This precision machine from Guyson Corp. was designed and built for grit blasting of medical implant devices. The expanded, two-station RXS-400 system has a small footprint and offers simultaneous dual operation.