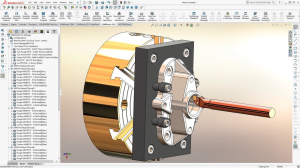

Turning hardened materials presents challenges, opportunities

Opinions vary on the definition of hard turning. Some industry experts say it's the single-edge cutting of hardened steels from 58 to 68 HRC, while others suggest hard turning begins at 45 HRC and includes hardened irons and superalloys. All, however, agree it presents difficulties but is quite manageable provided the right cutting tools, machine and process parameters are used.