)-291x300.jpg)

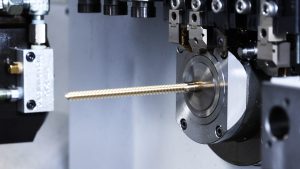

Gear tools for use on universal CNC machines

Advances in 5-axis CNC machining centers and turn-mill machines now enable manufacturers to cut gears with precision and efficiency—using specialized tools designed for multipurpose platforms. Star SU offers a range of tools that work with universal CNC machines to unlock gear manufacturing flexibility.