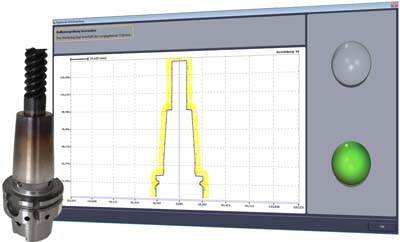

Tool RealityCheck

Is there a user out there that has never experienced the following situation? Programmed nominal data does not comply with real, actual data. A situation that can lead to costly collisions within the machine tool. With its new software module tool realityCheck ZOLLER has developed a solution to prevent expensive machine crashes.