Metrology service provider expands with second LK Metrology CMM

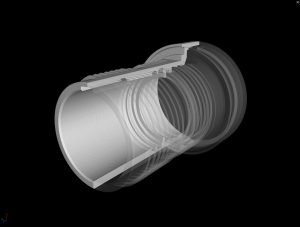

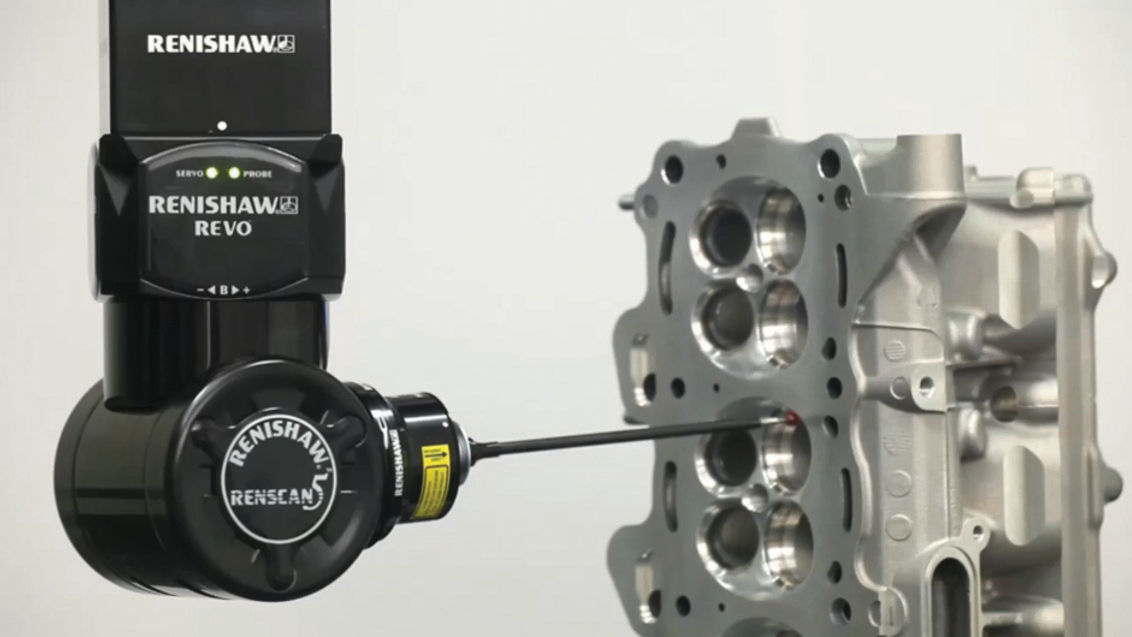

Contract inspection and reverse engineering capacity has doubled in terms of throughput, while the size of the component that can be measured has increased more than five-fold at Laser Scanning Ltd., based in Chapeltown, U.K., near Sheffield. It follows the installation of a second, larger coordinate measuring machine built by LK Metrology Ltd. at its Castle Donington, England, factory.