Suite of power-cutting control applications

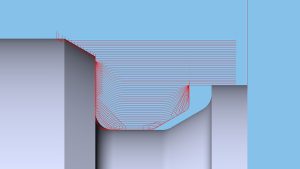

Machine tool idling, unnecessary pump rotation and continuously running peripheral equipment drive up machining costs. These energy wasters are in the crosshairs of a new suite of power-cutting control applications from Japanese machine tool builder Okuma Corp.