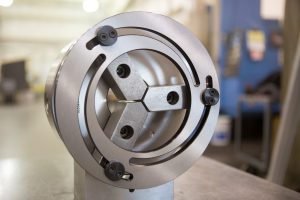

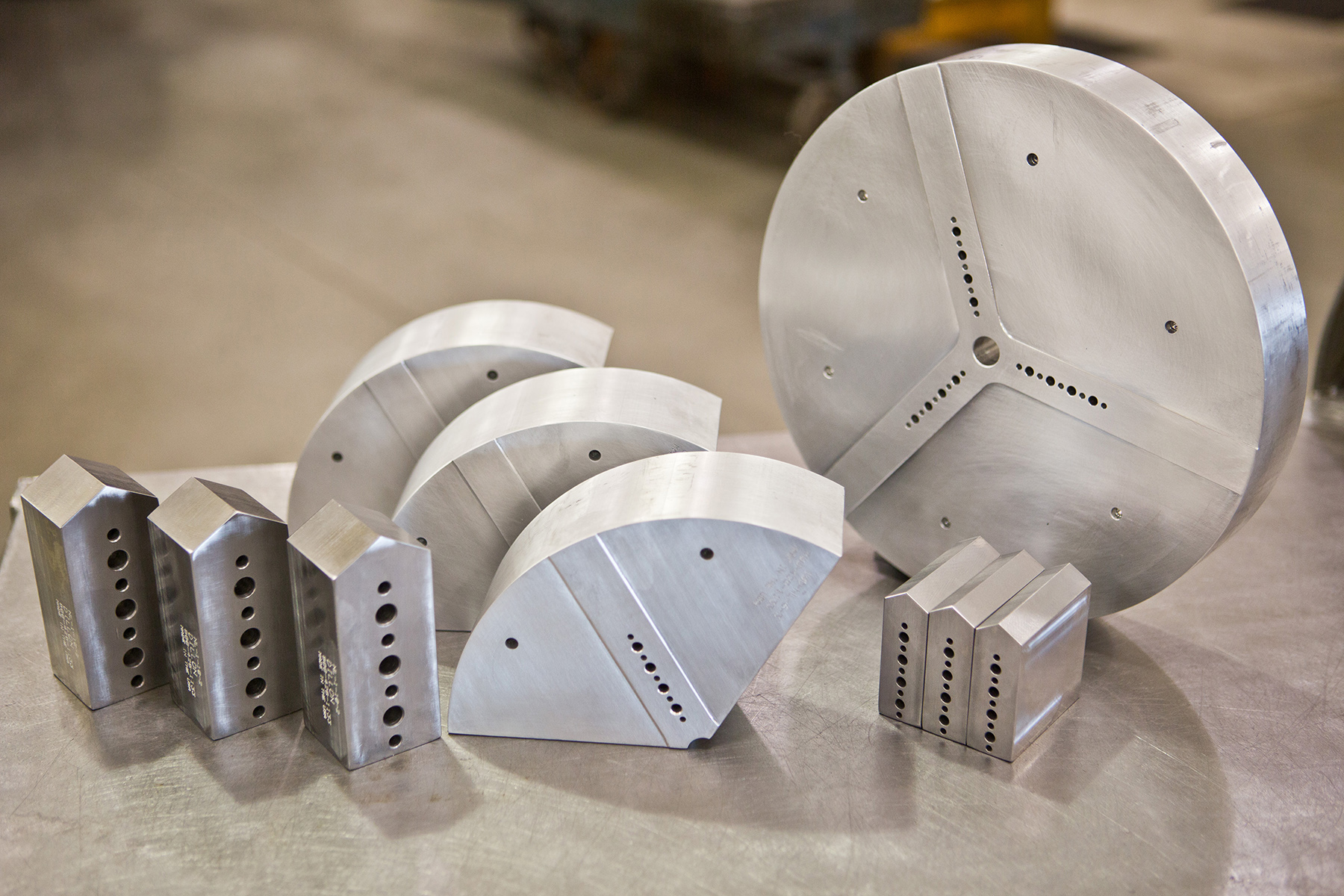

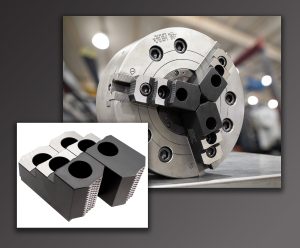

Extra-long hard jaws hold small diameter materials

Extra-long hard jaws from Dillon Manufacturing provide the extended reach that the company says allows the machining of smaller diameters, giving shops more versatility to handle a wider range of projects. The jaws are compatible with 8” to 15” power chucks, and are designed to maximize the potential of big-bore chucks, offering exceptional center reach...