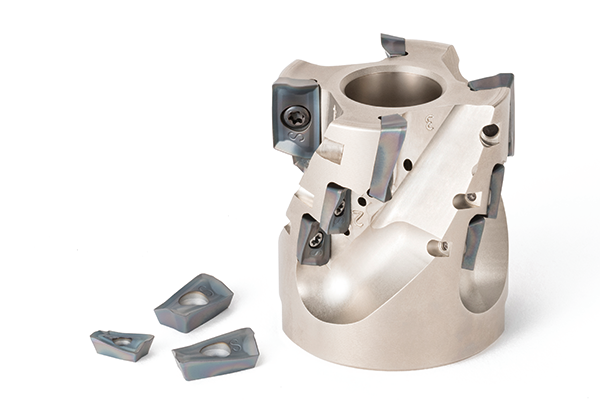

MECHT

The MECHT's unique holder design features a multi-stage insert combination for increased stability, rigid body for increased reliability, and coolant holes over each insert for excellent chip evacuation.