Amflex Self-Aligning Fixturing Elements

Amflex Self-Aligning Fixturing Elements

Advanced Machine & Engineering Co. announces the availability of the new Amflex Modular Workholding – S.A.F.E. Self-Aligning Fixturing Elements.

Advanced Machine & Engineering Co. announces the availability of the new Amflex Modular Workholding – S.A.F.E. Self-Aligning Fixturing Elements.

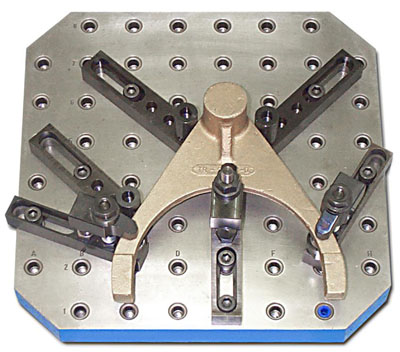

AMFLEX modular workholding components are designed to fit standard tombstones and grid bases but may be utilized with other traditional workholding systems. The components are designed for optimal clamping of a wide variety of parts and can by used on a variety of machine tools, both manual and CNC. Users are invited to contact AME to see how these products can benefit their specific manufacturing process.

S.A.F.E. elements use ball pads to support the workpiece. These ball pads are flexible and align themselves to the contour of the workpiece. The clamping bars also have ball pads, therefore distortion of the part is practically eliminated. When properly applied, the AMFLEX system reportedly guarantees flexible positioning and stress-free clamping.

The newly expanded Amflex Modular Fixturing product line includes hydraulic and pneumatic fixtures, modular components, S.A.F.E. grids, force cartridges, tombstones and high-density workholding systems for dedicated or manual fixturing.

A variety of precision grid bases, ball elements, spring supports, V-block supports, locators and clamping components are also featured to meet all current fixturing needs.