FCS Modular Clamping System

FCS Modular Clamping System

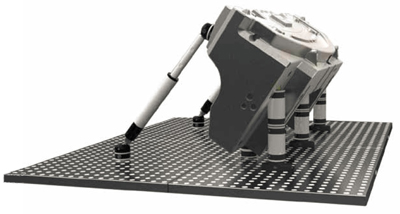

Single Source Technologies (SST) added the FCS Modular Clamping System (Breyl) to its product line.

Single Source Technologies (SST) added the FCS Modular Clamping System (Breyl) to its product line. This unique clamping system provides unrestricted access to five surfaces of the workpiece and enables operators to spend less time on setups and more time on machining.

"This modular system allows diverse fixturing options for any machining sector and turns hours of setup into minutes," said Darrell Johnson, product manager milling consumables at SST. "Companies have reported increasing production time by 88 percent on average with this system, which translates into higher machine utilization and lower costs. Additionally, faster equipment and pallet changes mean a more standardized work process for improved part quality and consistency."

The system uses virtual design during the CAD/CAM stage of part production to project a grid on the workpiece that calculates the best way to attach the part for machining and chip evacuation. After checking for possible interferences with other holes, it automatically arranges the fixing seats based on the dimensions of the workpiece and combination of pallets and clamping available.

Permanent reference points enable easy removal and reassembly of the workpiece on the pallet or base gauges to keep the zero reference point locked" This design facilitates engineering changes or part repair, and the original mounting holes enable quick reclamping at the same point. No special equipment or standard maintenance is needed for this system.