Minor Version Update to ProNest 2019

Minor Version Update to ProNest 2019

Hypertherm announced a minor version update to ProNest 2019, its advanced CAD/CAM nesting software for automated cutting. This new release contains targeted features and enhancements designed to make customers more efficient and profitable.

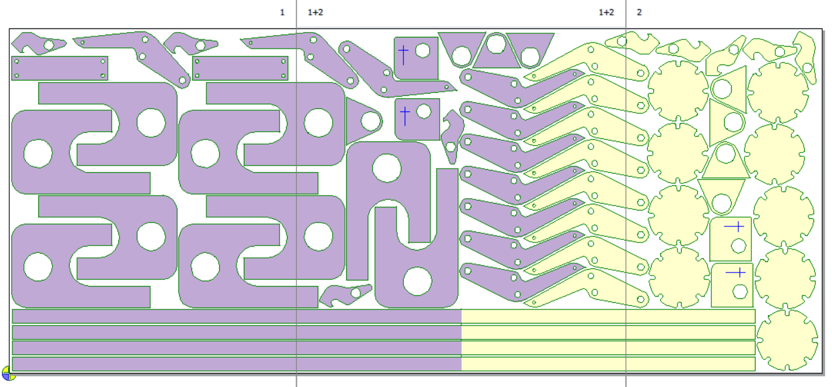

Hypertherm announced a minor version update to ProNest 2019, its advanced CAD/CAM nesting software for automated cutting. This new release contains targeted features and enhancements designed to make customers more efficient and profitable. New features include:

- PDF import so programmers and operators can directly import vector-based PDF files such as engineering drawings or specification sheets, eliminating the need for separate .dxf and .dwg files to make the importing of parts and job quoting easier and faster.

- Scribe text additions that make it possible to automatically mark parts during import with unique identifying information such as a part name, customer name or work order number.

- Reposition work zones allows parts to span multiple work zones in a single nest as reposition machines can now cut parts in sections, beginning the cut in one work zone before repositioning and completing the cut in another zone.

"These feature additions incorporate feedback directly from our customer base, providing users with the specific tools they need to increase both productivity and profitability," said Tom Stillwell, marketing project manager for Hypertherm CAD/CAM software products. "At the same time, the software remains easy to use with a highly intuitive user interface that benefits both new and experienced users."

In addition, Hypertherm is announcing several major improvements to its ProNest LT software, designed for light industrial cutting. New features being added to ProNest LT include:

- Cutting techniques used to specify how parts should be cut based on sections of a part's geometry. For example, automatically adjusting cut speeds for corners, leads and arcs.

- Automatic height control can be automatically disabled based on certain parameters such as interior profile size, crop cuts, skeleton cuts or lead-outs.

- PDF import will also be included at the LT level.