Needle Sharpener

Needle Sharpener

Phoenix Medical Products is a Mountain City, Tenn., contract manufacturer of various devices used in the thoracic, laparoscopic, arthroscopic, gastrointestinal, cardiovascular, soft and hard tissue biopsy areas of the medical and research markets. As such, their watchword is precision at every turn.

Phoenix Medical Products is a Mountain City, Tenn., contract manufacturer of various devices used in the thoracic, laparoscopic, arthroscopic, gastrointestinal, cardiovascular, soft and hard tissue biopsy areas of the medical and research markets. As such, their watchword is precision at every turn. In addition to mold design, injection molding and various machining services such as milling, turning, grinding and drilling, Phoenix also maintains a complete Class 10,000 cleanroom packaging and labeling facility. They offer their customers a competitive edge by being a turnkey operation, from CAD through rapid prototype, validation, production and packaging. Even product printing, etching and laser marking are done here, along with catheter tipping and Nitinol wire forming and crimping, making a Phoenix a true one-stop shop for most customers.

As with all such operations, a bottleneck at any stage can create both upstream and downstream problems. With a variety of demanding customers and diverse jobs that all require the ultimate care in precision handling, this 20-year-old, 107,000 sq. ft. shop is constantly on the lookout for newer, better ways to produce their products.

One department at Phoenix is devoted entirely to needle design, production, sterilization and packaging, as this work has a unique set of challenges and all the attendant concerns of any machine shop that does work in the medical market. As David Hannah, general manager for needle production explains, "Our former method for one type of needle production involved sharpening with a 5-axis CNC grinder and manual fixture. The needles needed to be end-swaged down to a particular and different diameter, which was not a very precise process. When we'd set up the CNC grind, we'd often need to run some parts two or three times to get the desired edge because the swage did not leave us enough usable material."

Hannah and Phoenix engineering manager, Chris Blake, set out to find a solution. As Hannah explains, "We first did a web search and, after a couple of calls, found Advanced Machine & Engineering (AME), a new supplier for us. After speaking to their engineers several times, I knew we had a good match. The entire process with them was very simple and straightforward. They sent an engineer down to see our process and our current manufacturing, which we appreciated."

That engineer was AME's Dan Lapp, vice president of sales for the company. After the initial visit, the AME design department went to work. After a series of discussions, the SolidWorks model was ready for review. Only minor modifications were required by the Phoenix team, after which the first unit was built, entirely at AME, itself a contract machine builder with decades of experience in the metalworking market.

The company also designs and manufactures extensive lines of carbide sawing equipment, as well as machine tool components such as spindle interfaces, gears, workholding devices, machine covers, chip conveyors and custom fixturing, as well as a complete line of safety products, including rod locks and safety catchers for fall protection.

Once the first machine was built, it underwent extensive testing on Phoenix needle products, using an in-house grinder at AME to test accuracy, surface finish, part-to-part time and the machine assembly itself. Upon shipment and commissioning at Phoenix, the machine was immediately put into production. To the great satisfaction of the customer's production team, this needle sharpener was found to be highly productive, from the outset.

As Hannah notes, "With this new fixture, we were able to set the products up on our manual grinder and a surface plate. Using our video system, the operator could observe each needle being ground and achieve the correct point on the first cycle, every time. As a result, in a very short time, we were able to track a 40 percent increase in our production plus a 5-10 percent decrease in scrap."

This latter number is quite significant, as the raw material for such needles is typically an expensive 304 or 17-7 stainless steel. Hannah further observed the entire operation was now simpler and much easier for the operator to execute, with less set-up time and reduced maintenance. Since its start-up at Phoenix, the needle sharpener has needed only one routine cleaning.

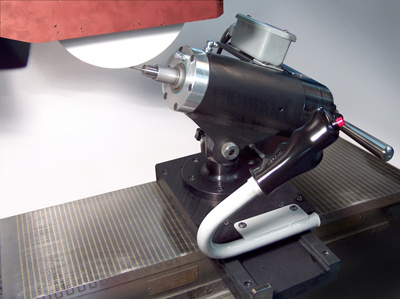

In production, the AME needle sharpener enables a double loup conical point to be machined. It was also designed to allow Phoenix the latitude to change cam plates and grind a variety of style points. The needle sharpener provides workpiece rotation and axial motion (oscillation) simultaneously. Rotation is provided by a dustproof, watertight gear motor through a drive system. Oscillation is provided through the built-in cams. The typical needle workpiece oscillates twice for .025"/.028" per rotation. The spindle assembly tilts from 0 degrees to 40 degrees around the pivot point (shoulder bolt screw) and locks in any position to provide an optimum sharp edge on the workpiece. Tolerances are routinely held to the Phoenix standards, namely, plus or minus .001" on straight grinds, plus or minus .002" on double loup grinds.

The original machine purchased was designed for a line of Phoenix needle products that was subsequently modified but the needle sharpener was quickly adjusted and back in production in a very short time, according to Hannah, who notes he would have "zero reservations" about recommending AME for future work at his company.