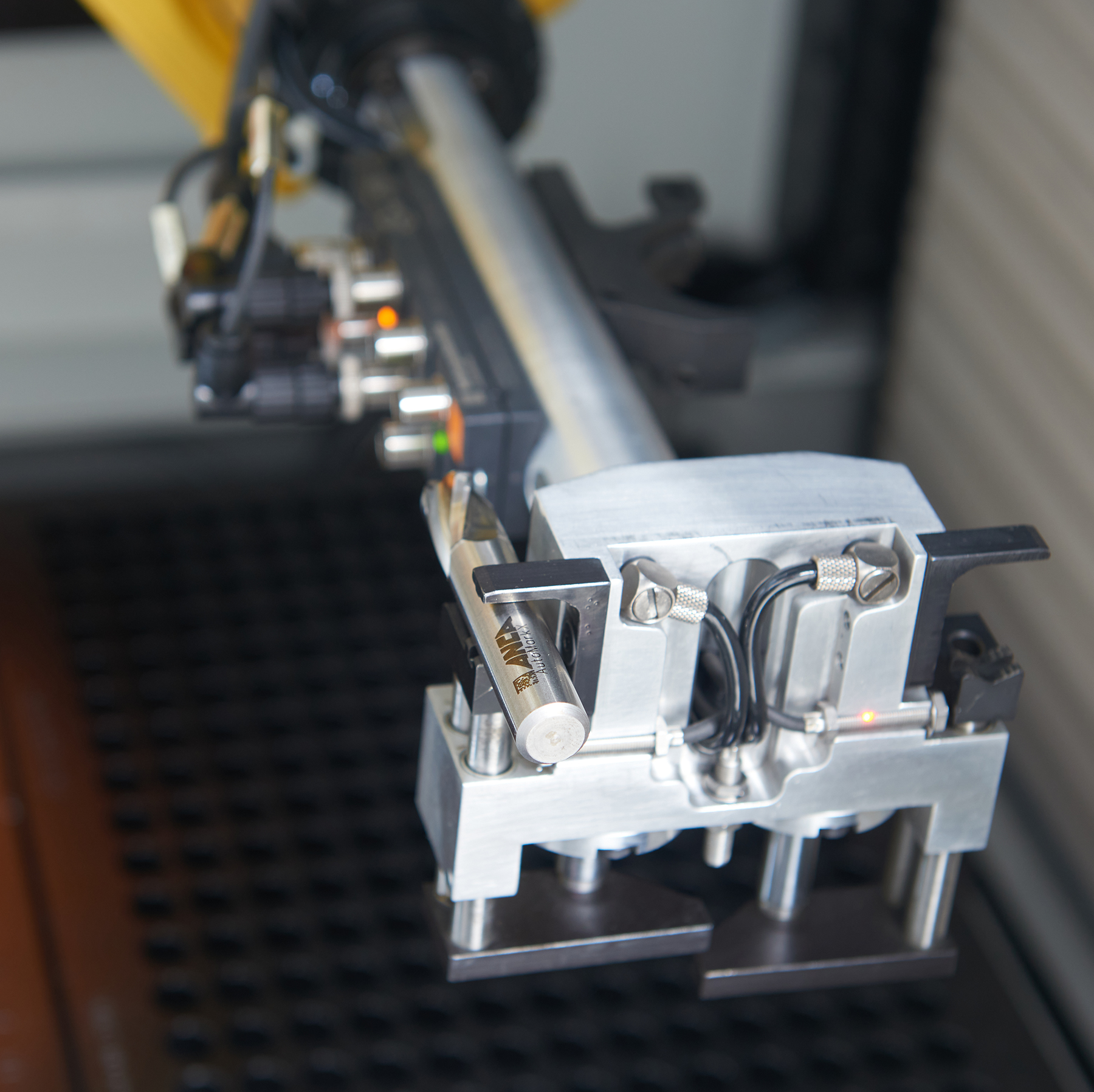

AutoMarkX

Tool manufacturers are seizing options that streamline processes and save labor costs. AutoMarkX is capable of automated pallet loading and takes care of the tool laser marking process, freeing up operators to perform more value-adding tasks. AutoMarkX is designed for integration with AIMS, being able to automatically receive and dispatch pallets from AutoFetch, while connectivity to the AIMS Server provides details of the message to be marked on the tools.n