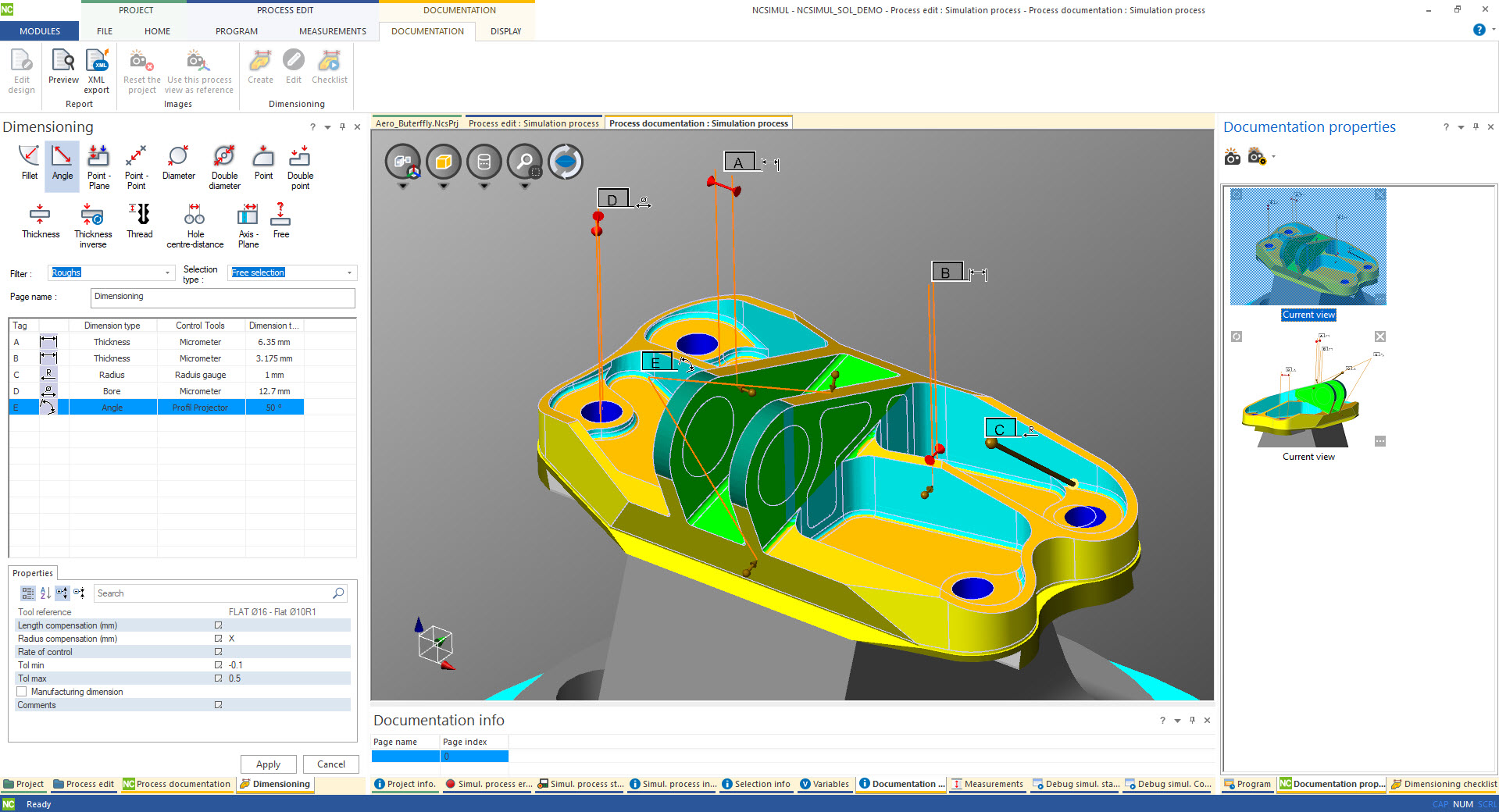

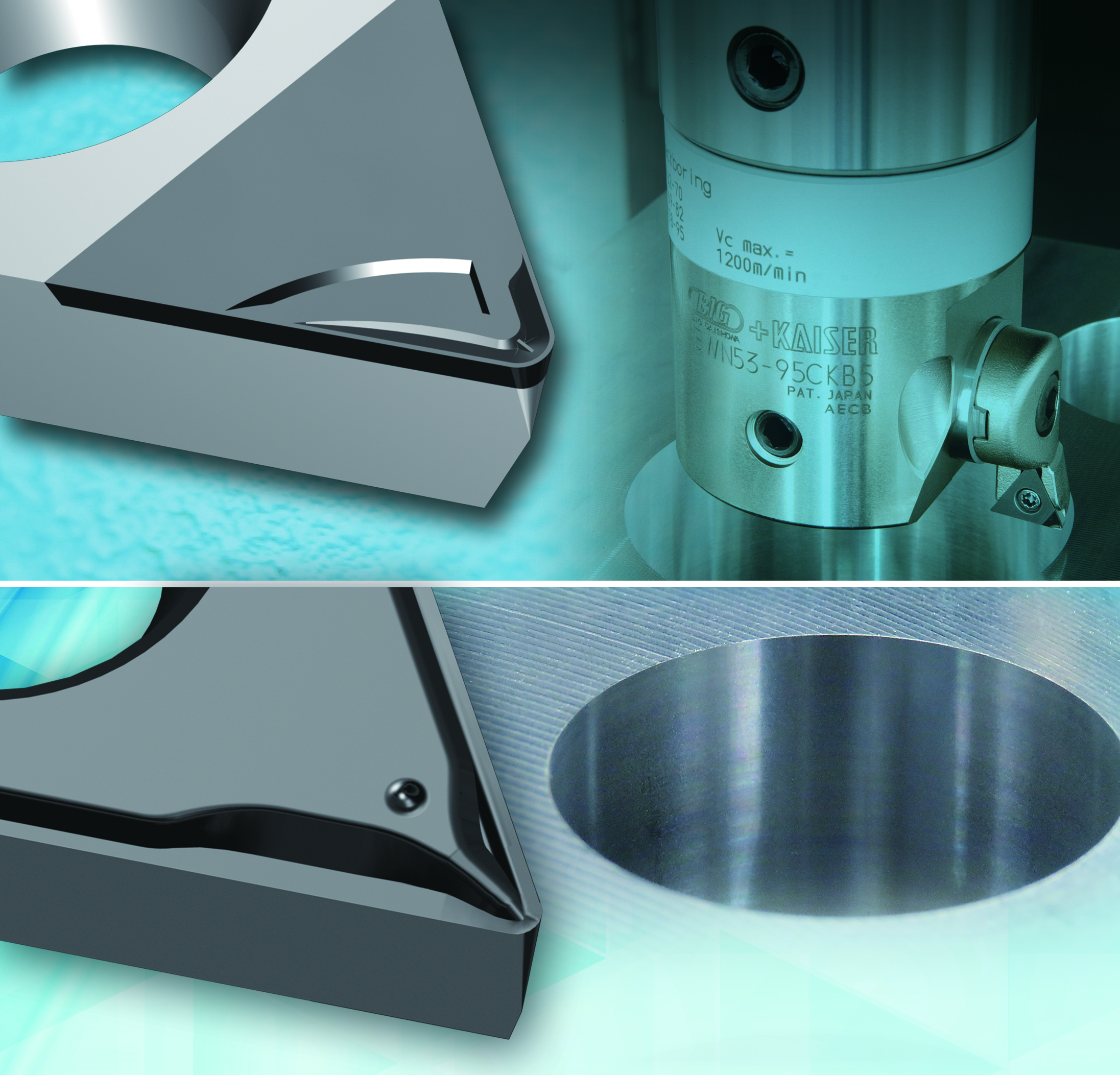

Xtra·tec XT M5130 Shoulder Milling Cutter

The mill is best suited to machining steel, stainless steel, cast iron, non-ferrous material and materials with difficult cutting properties. This wide range of uses results in lower tooling and administrative costs, as does the fact that its 90° approach angle dramatically decreases the need for finishing operations. Walter Tiger·tec cutting tool materials, the high number of teeth, and small indexable inserts also makes it ideal for workpieces with small machining allowances.n