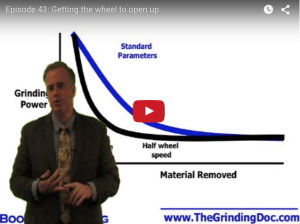

Keep the sweet spot

A shop that cylindrical-grinds tungsten-carbide is running into trouble maintaining optimal parameters when switching to a larger diameter. Dr. Jeffrey Badger, the host of Cutting Tool Engineering's Grinding Doc Video Series, offers some insight.