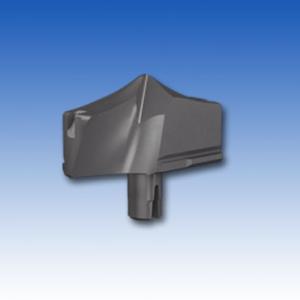

Guhring Solid Carbide Drill RT 100 InoxPro – 50% Higher Feed Rate in Stainless

Guhring introduces a breakthrough in drilling stainless steels with the RT 100 InoxPro solid carbide drill. This innovation combines carbide, geometry, and a specially tailored coating, resulting in exceptional performance. The drill extends tool life and reduces machining times, addressing challenges posed by stainless steel's high temperatures, tendency to jam, and promotion of tool wear.