July 2019

Articles in this issue

Part manufacturer seeks to oust weak machining link

Rotary broach that lasts for 1,000 parts helps company enable lights-out machining.

Make a name for your company with community involvement

You can't say yes to every request but volunteering your time can be good for business.

Boring: Calculating deflection

Eliminating chatter, especially when boring deep holes, is one of the greatest machining challenges.

Inside the impact of inserts

CNC machines loaded with indexable tools are the foundation of modern machining.

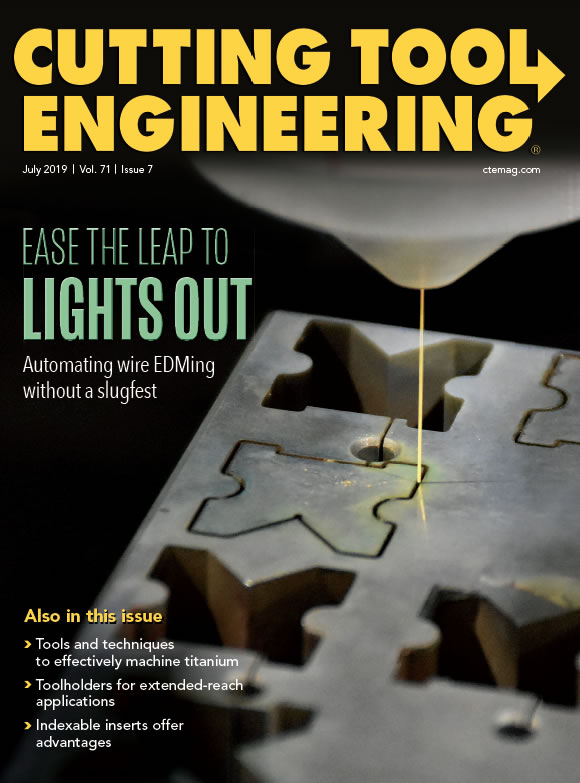

Turn out the lights on wire EDMing

Of all machining processes, wire EDMing is perhaps best suited for lights-out manufacturing with one exception, slugs.

Company benefits or lack thereof

Columnist Michael Deren compares company benefits. How does yours stack up?

Unorthodox machining odds and ends

Try these tips from machinist and moldmaker James Harvey in your shop.

Spindle sensor enhances safety

B-Safe from Balance Systems detects collisions during machining, preventing damage to parts and machine.

Additive approach to machining Ti6Al4V

Tool blanks are printed to make cutters to machine titanium.

Catching ’22’: Beat the challenges of titanium

Effectively machining titanium alloys requires suitable cutting tools, machine tools and monitoring systems.

Focusing on high-speed inspection

With the new Taglens-T1 varifocal lens, manufacturers can achieve high-throughput noncontact parts inspection.

Extended-reach toolholders remain a requirement

Multiple-axis machines increase workpiece accessibility but some jobs still require these specialized toolholders.