Tungaloy expands PVD Grade for broader milling spplications

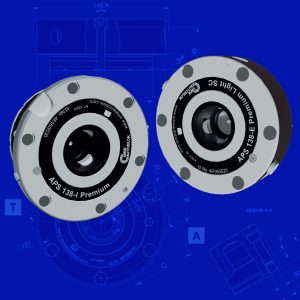

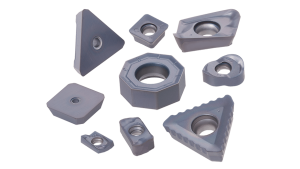

The AH3225 PVD-coated grade tooling from Tungaloy Corporation is now available across a wider range of milling tools including high-feed cutters (MillQuadFeed), face milling cutters (DoOcto), shoulder milling cutters (TungTriShred), and ISO insert geometries such as SDKN42 and TEEN32.