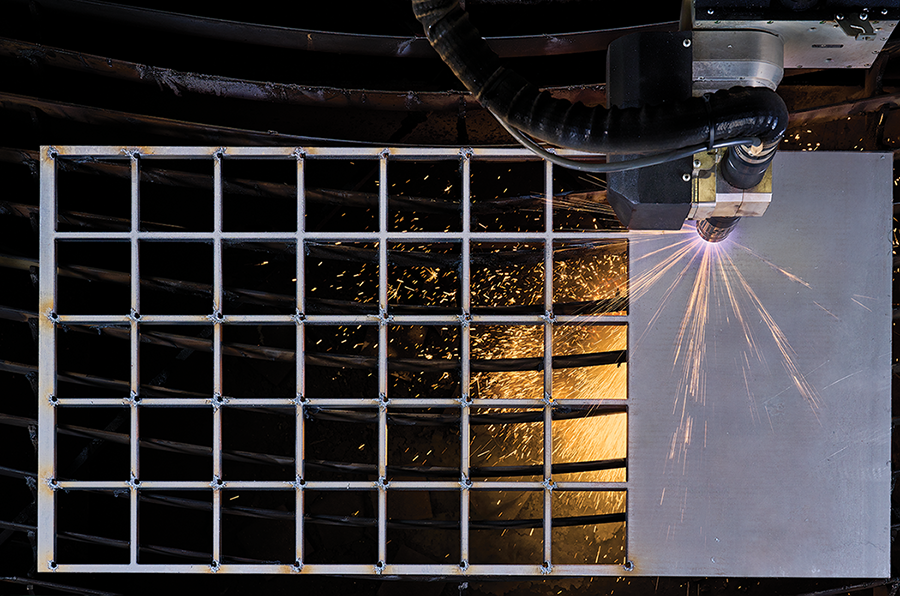

Z-Mag DTM Portable CNC Drill and Tap Machine

The unit accommodates different height applications with an available 13 inches of stroke, 1,300 lbf. of thrust and spindle speeds of up to 3,000. Using an HSK style spindle adapter, operators can use a variety of HSK tool holders. The sturdy cast iron frame, linear rail system, and precision ball-screw feed system provide a solid foundation for any application, from light roughing to finishing.