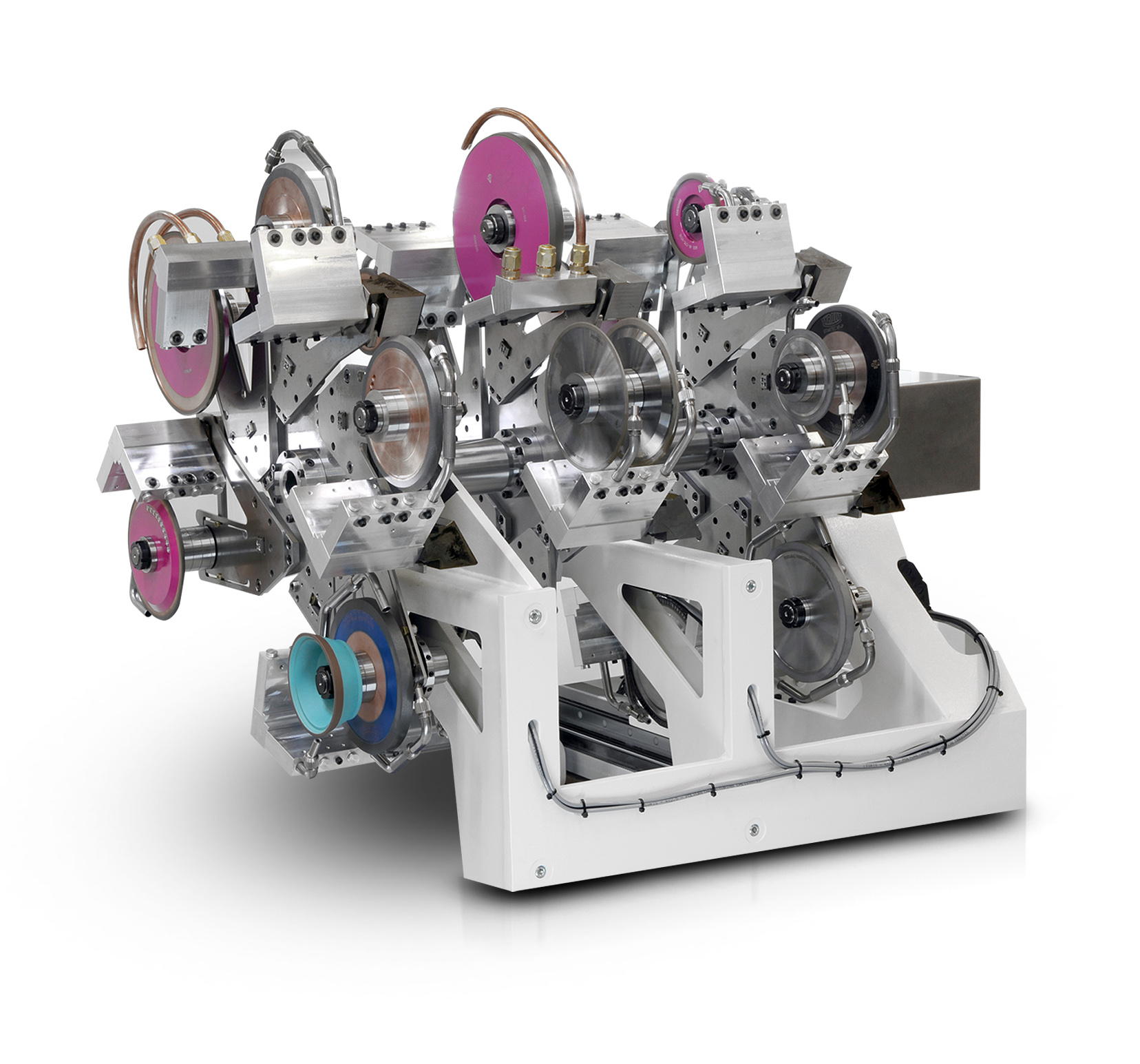

Zerolox XP 80Z Zero Point Workholding Automation Console

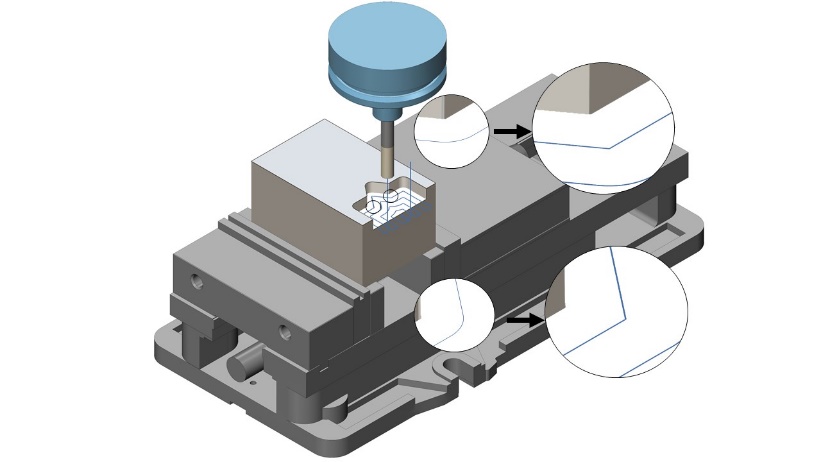

The ZeroClamp Zerolox Zero Point Automation console is the only Zero Point product like it on the market today. It is superior both in repeatability and clamping force to single Zero Point workholding units having only 1 clamping stud with an orientation pin or slot. In addition to manual mechanical plate Zero Point clamping systems using 4 V-notched studs on a 52/96 mm spacing which requires clearance in multiple geometric planes.