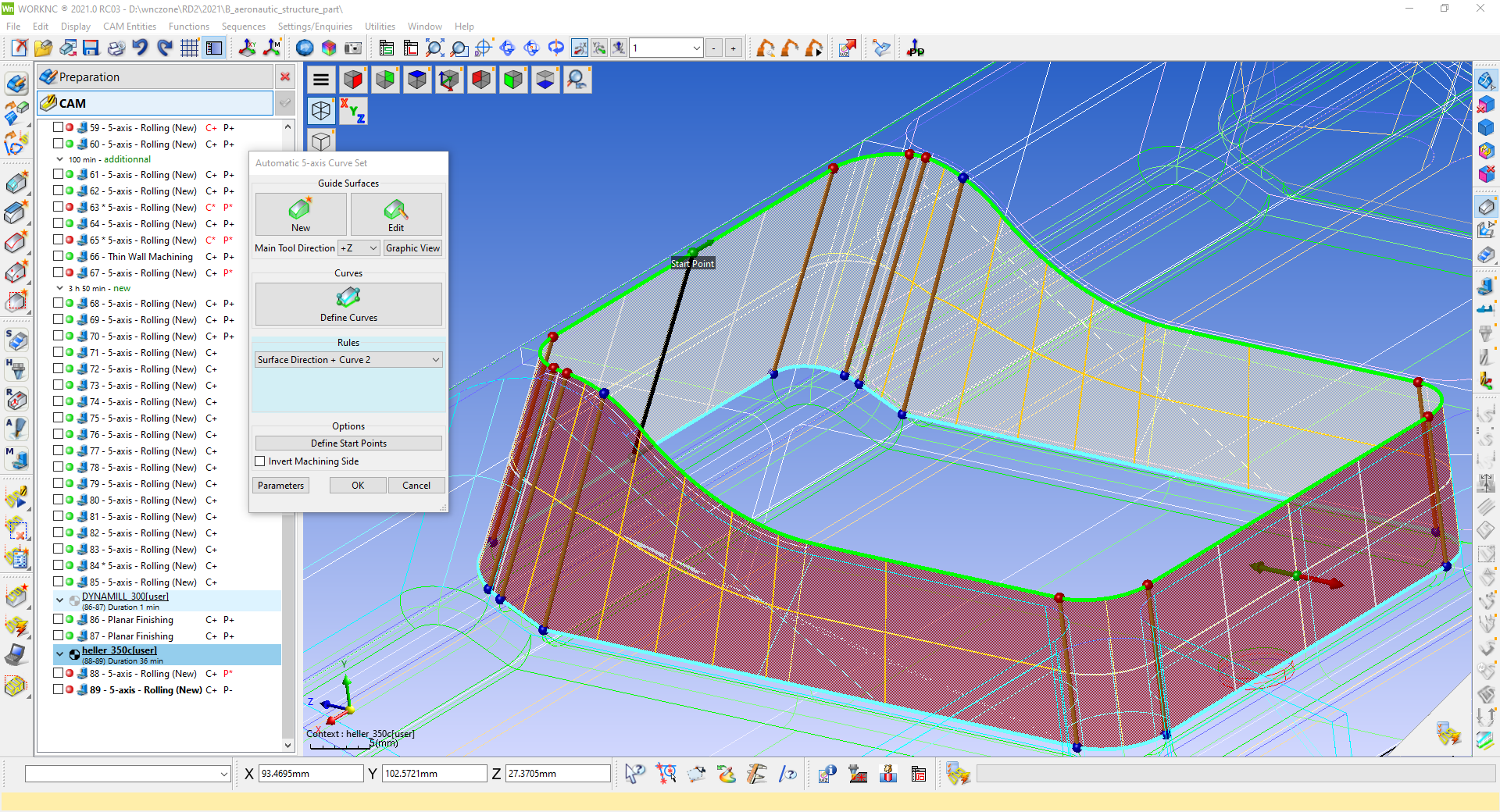

Enhanced Parallel Finishing toolpath in WORKNC 2021

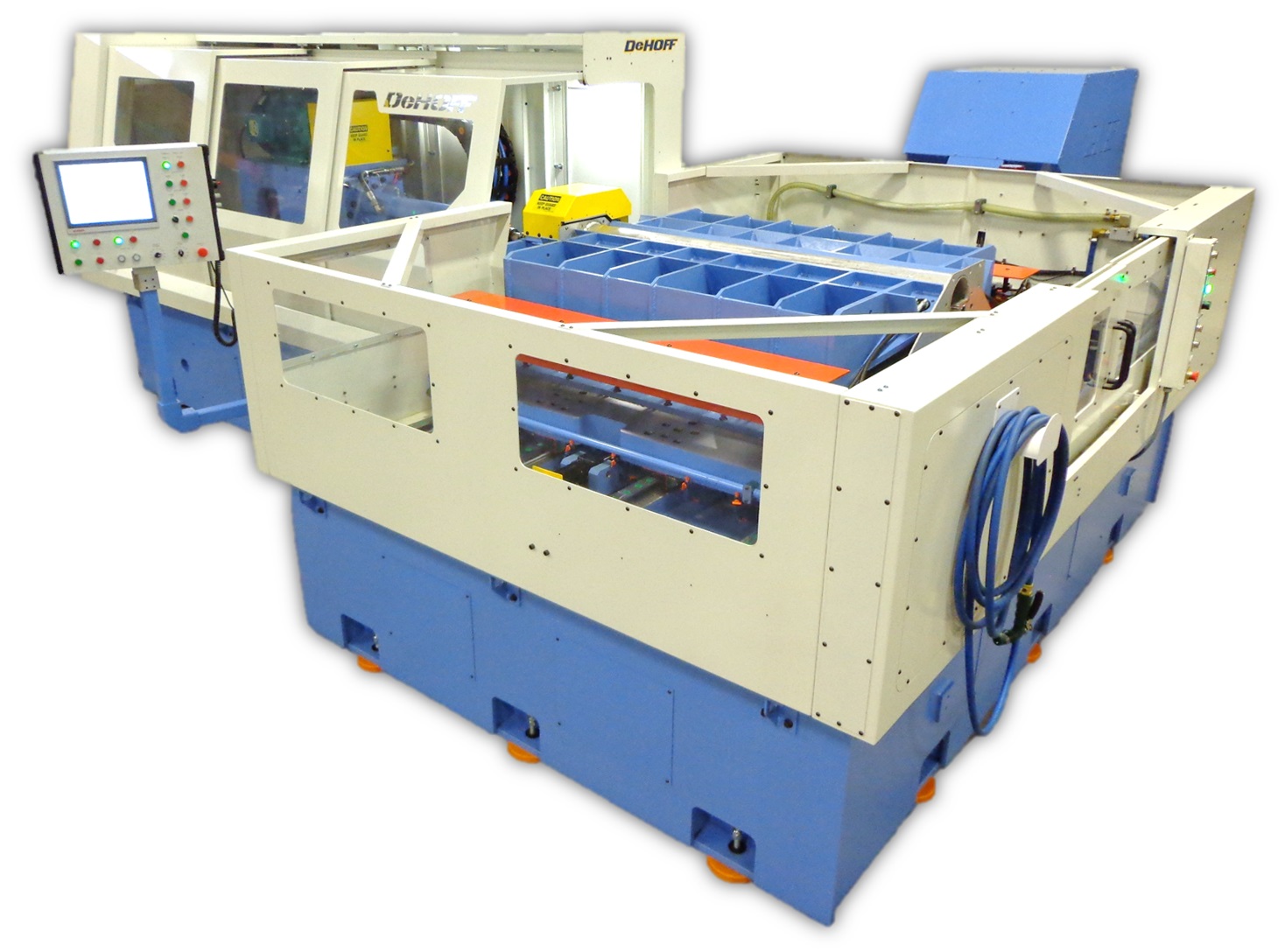

Another important feature in the latest release of the software is the New Part centering/probing function, which generates pointset nodes for any inspection machine or direct CNC part inspection on a milling machine. Additionally, a new Probe Inspect command creates and exports control points in the CAM project to feed a probing system. There are also specific improvements to part centering tailored for CNC machines with table palletization. n