HX Jobber Drill

The PTD HX can deliver up to 70% more holes in moderate conditions. The versatility of the industry's "Go-To" jobber drill extends beyond medium strength materials, delivering 18% more holes in heavy conditions and up to 30% more holes in light conditions.

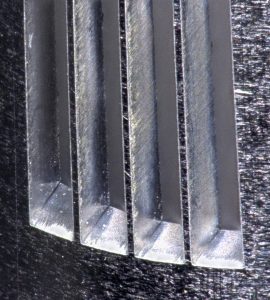

-scaled-300x300.jpg)