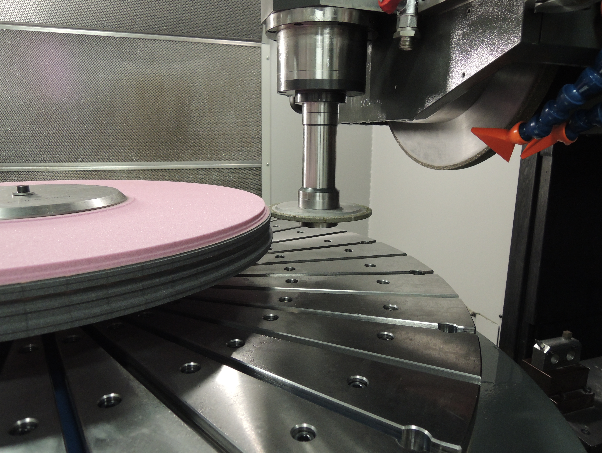

Leo Peri 4-Axis Grinding Center

AGATHON Machine Tools Inc. has introduced the new Leo Peri 4-axis grinding center for grinding the periphery of indexable inserts. Throughout product development, the Leo Peri design concept focused on achieving a smaller machine size, incorporating greater user friendly accessibility, maintenance free concepts, and overall superior machine strength enabling high process performance to meet both high production and peak quality standards for carbide, cermet, ceramics and PCBN applications.