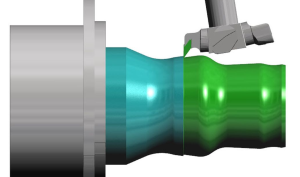

Look Ahead: Trochoidal endmill (over)laps competition

Trochoidal milling is a relatively new cutting strategy that involves the overlapping of circular toolpaths with linear movement. It is well-suited for difficult-to-machine materials and thin-walled components.