Episode 74: Norton SG grits Q&A

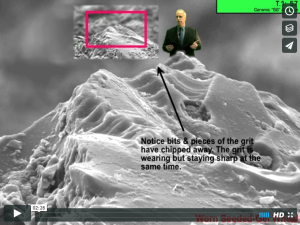

A shop asks Dr. Jeffrey Badger about applying Norton SG grits in the 74th episode of Cutting Tool Engineering magazine's Grinding Doc video series.