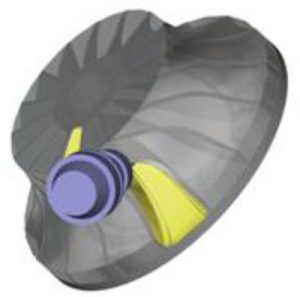

Can milling compete with grinding for rapid stock removal?

Many times in making parts for aerospace engines with high temperature alloys like IN-718, Rene-95 and Waspaloy it is necessary to remove large amounts of material. Traditionally companies use, milling, turning or broaching to remove most of the material and then finish-grind to size. The engineers at Norton/Saint-Gobain's Higgins Grinding Technology Center have determined that for these materials grinding can, in many instances, remove the material more quickly and economically than turning or milling.