Products

•

June 1, 2014

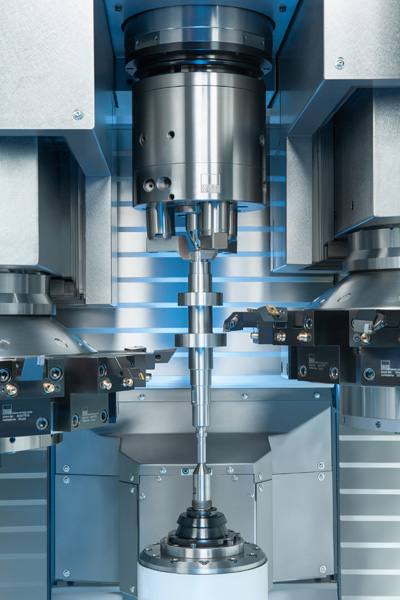

VL 8 Vertical Pickup Turning Machine

The market for commercial vehicles is experiencing a vibrant development. Emerging economies have a growing need for new technologies in the production of semitrucks and agricultural machines, enabling them to achieve the desired growth in the construction industry and agriculture. New manufacturers from China, for instance, intensify the price war, putting today's production planners under considerable pressure. The future of commercial vehicle production lies in being faster, more energy efficient and increasingly flexible. EMAG, with its VL 8 vertical pick-up turning machine for workpieces up to 16 inches in diameter, offers a solution for the production of commercial vehicle components.