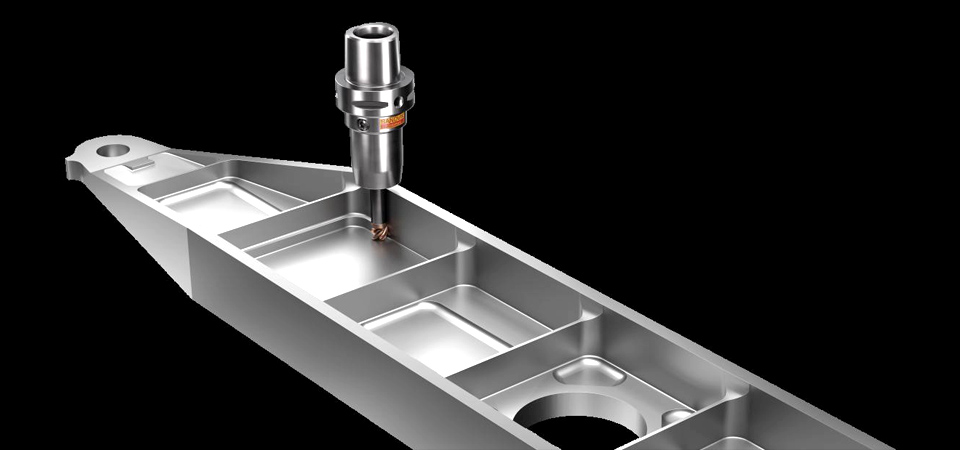

Flat stones for fine finishing

Abrasive stones commonly found in machine shops are fine for run-of-the-mill deburring and abrading, but absolutely not suitable for precision stoning. For that, you need a pair of carefully prepared, precision-ground flat stones.