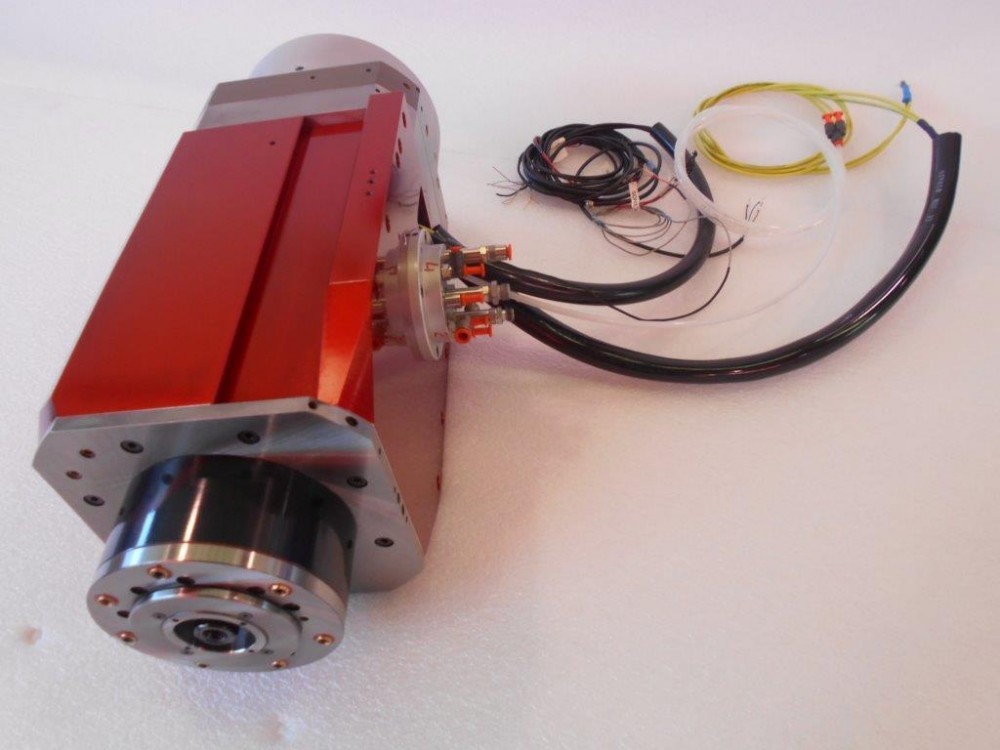

Modular toolholder finds its groove

END USER: Premier Industries, (763) 786-4020, www.premierind.us. SOLUTION PROVIDER: Horn USA Inc., (888) 818-HORN, www.hornusa.com. CHALLENGE: Reduce cycle times, extend tool life and impart finer surface finishes when parting off parts for pressure regulators. SOLUTION: A modular toolholding system.