Report predicts steady growth for waterjet cutting machine market

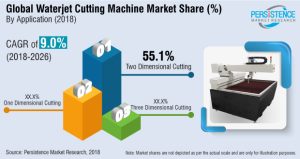

According to a findings specified in the report on the waterjet cutting machine market, the market is expected to witness steady growth over the forecast period (2018-2026), led by increasing industrialization and manufacturing sector in emerging regions across the globe. The long-term outlook for the global waterjet cutting machine market is expected to remain positive and the market is expected to expand at a CAGR of 9.0% during the forecast period.