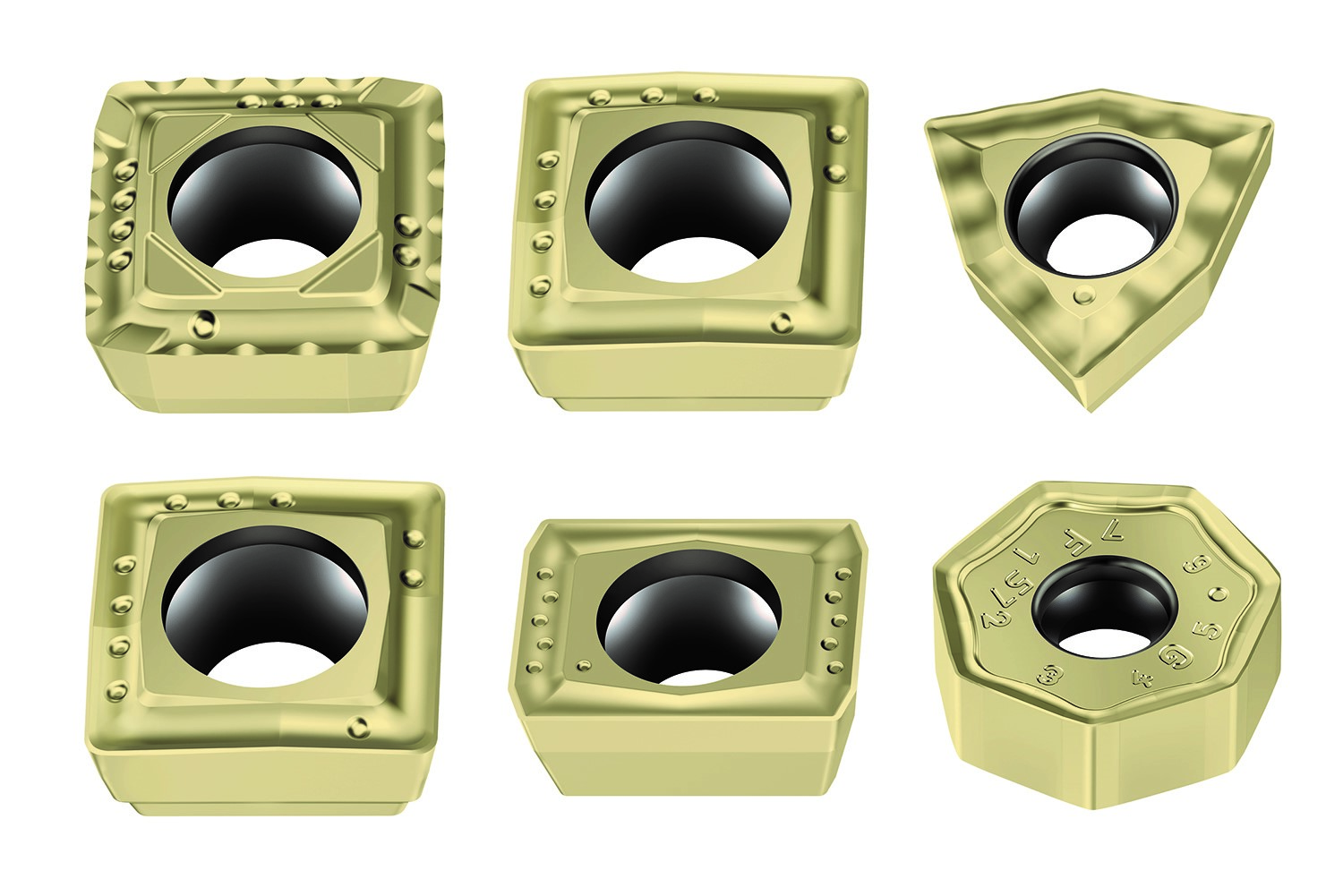

New tools for coupling and pipe machining

Continuous development of customer-focused tool solutions is the idea behind the growth of Paul Horn GmbH, suppliers of cutting tools for manufacturers of machine tools for pipe and coupling production, as well as end users.