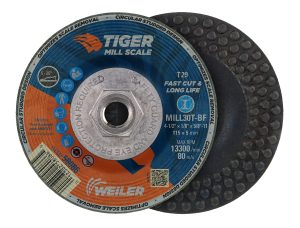

Abrasive wheel removes mill scale

The Tiger Mill Scale wheel from Weiler Abrasives is an abrasive product designed to quickly and efficiently remove mill scale from hot-rolled carbon steel. This new addition to the Tiger portfolio provides a targeted solution for industries such as shipbuilding, pressure vessel manufacturing, and metal fabrication, where heavy mill scale removal is critical for weld...

-scaled-300x225.jpg)

(1)-scaled-300x204.jpg)